The positioning principle and method of automobile checking fixture

The positioning principle and method of automobile checking fixture

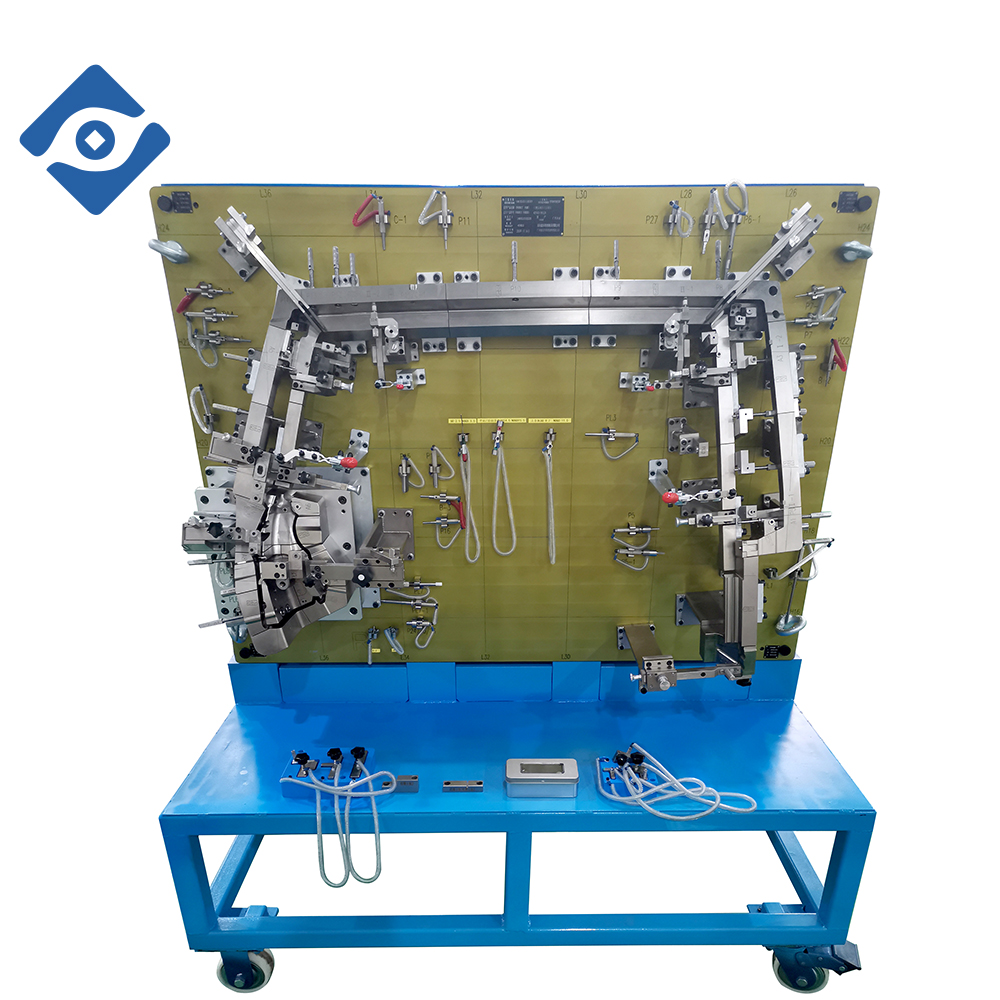

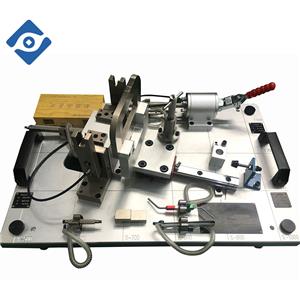

To check auto parts, the first thing to do is to fix the part. If the part is loose, the measured result is not usable. Therefore, if we want to check auto parts, we must first fix the parts, which is often referred to as positioning. How is the positioning of the automobile checking fixture different? Fidelity Inspection Fixture Manufacturer(Abbreviation: FIFM) will answer your questions.

We all know that in polygons, triangles have stability. Similarly, the positioning of auto parts products in the three-dimensional coordinate system must satisfy the positioning in three directions in the three coordinate systems, that is, the positioning in the X, Y, and Z directions. The X direction is divided into positive and negative, and the same Y and Z directions are also divided into positive and negative. Here, the positive and negative directions of X, Y, and Z are collectively referred to as the X, Y, and Z directions.

In the design of automobile checking fixtures, the commonly used positioning methods are the main and the sub-datums with the clamps to positioning. The main datum generally controls positioning in two directions, such as X-Y, X-Z, and Y-Z directions; the secondary datum controls one direction, such as X, Y, and Z directions; the clamp is pressed on the zero surface, and generally controls one direction, such as control X, Y, Z directions. In the space coordinate system, the general positioning method can be like this.

According to the specific type of the product, the positioning form is also different. Some products are positioned by using positioning holes, and some products are positioned by the edge and surface of the product. No matter what the positioning is, it revolves around the principle of positioning in three directions in space, otherwise, the phenomenon of unstable positioning will occur. And it's not that the more positioning, the more better it is. The over-positioning will also affect product measurement. But no matter what the positioning form of your product is, FIFM can create a satisfactory positioning method.