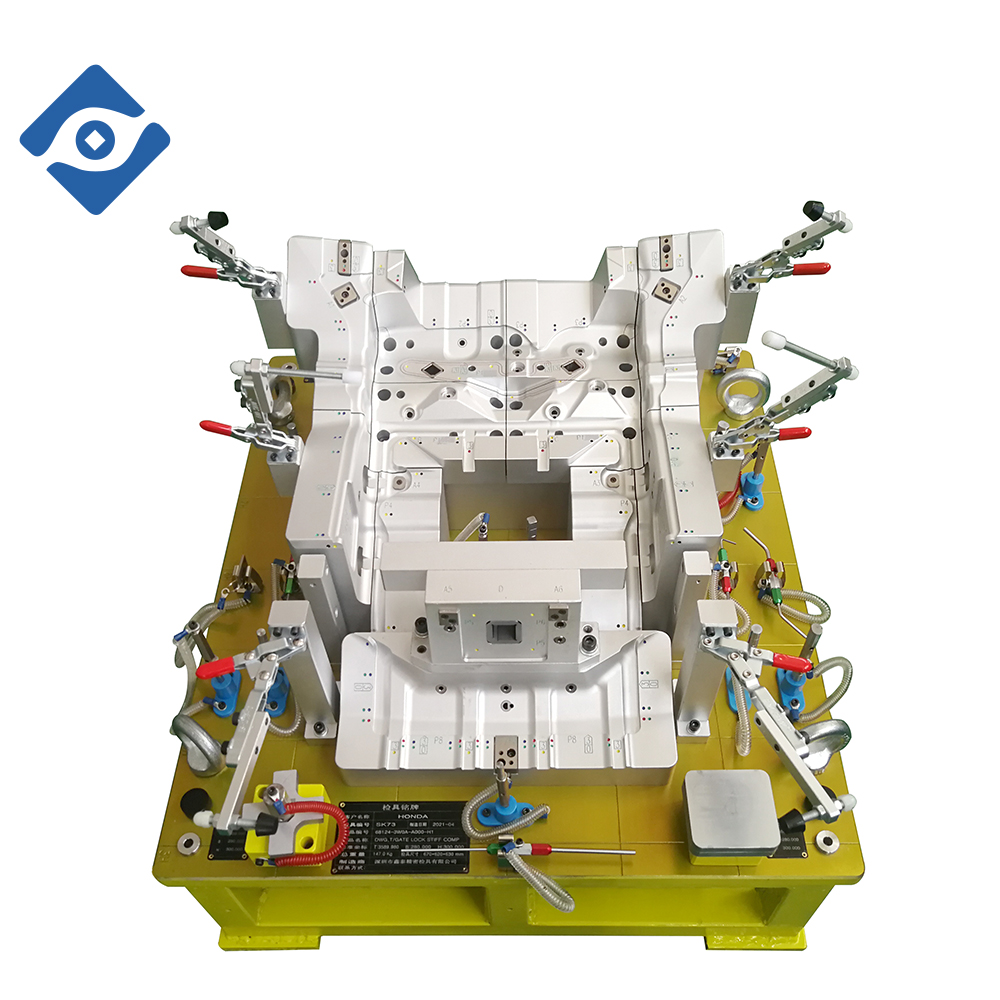

Automotive checking fixture positioning pin

Automotive checking fixture positioning pin:

- The position of the positioning hole is determined according to the part drawing RPS system (usually two positioning holes are set for each part).

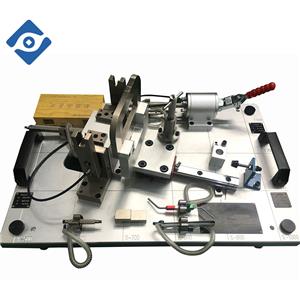

- The positioning pin consists of three parts: guide, positioning and handle, to ensure that the guide part of the pin can enter and exit freely in the positioning hole.

- Marking of positioning pins: mark the pin specification and the corresponding RPS point name in the handle recess.

- According to the RPS characteristics of the part, the positioning pins are correspondingly set into tapered pins and cylindrical pins.

- In the positioning hole, in order to ensure the accurate positioning of the positioning pin, a guide bushing must be installed, and the guide bushing and the gauge body must be fixed as one.

- The positioning accuracy of the center of the guide bushing relative to the body coordinate line is controlled within +/-0.05mm.

- The structure of the positioning pin and the corresponding guide bushing can be divided into anti-rotation structure and non-anti-rotation structure according to the different requirements of the shape of the hole.

- Each positioning pin is equipped with Ф3mm nylon rope and fixed to the appropriate part of the checking fixture body.

- Placement of the pin box : After the positioning pin and the checking pin are used, they should be placed in the pin box and clamped with a collet. The pin box is placed in the proper position on the side of the checking fixture body and the upper part of the base plate.

- In the drawing of the checking fixture, the positioning pins and positioning holes must be clearly stated.