Automotive checking fixture process

Automotive checking fixture process

Good automotive checking fixture technology is an important prerequisite for cost, quality and delivery time for checking fixture factories. The automotive checking fixture process should be arranged according to specific projects. After the design department completes the design plan, it should start to formulate the corresponding process. In our previous actual work, we sometimes encounter cases where the process arrangement is unreasonable, which makes it difficult to guarantee the accuracy of the parts, and causes the parts to be scrapped and affect the delivery time of the finished product. But we have now mastered most of the processing technology and strive to do better.

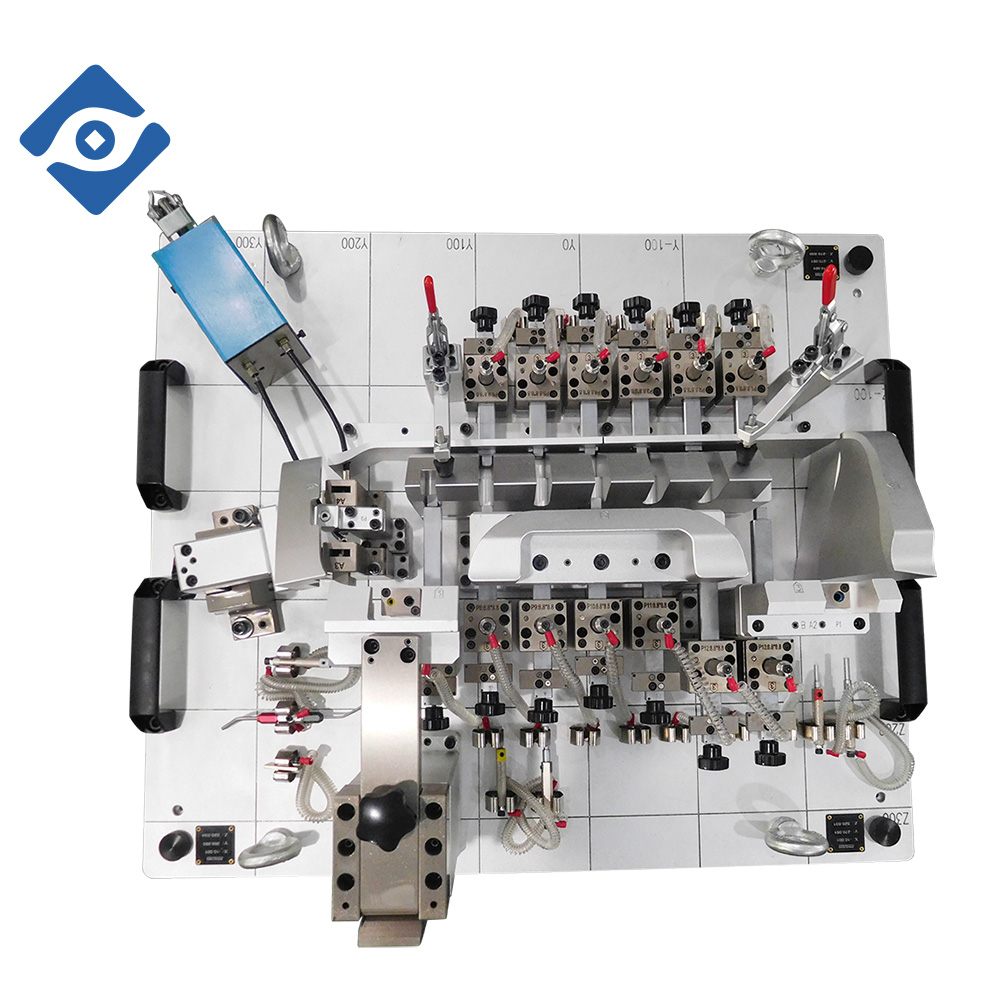

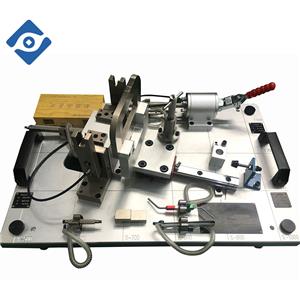

Checking fixture parts processing according to the type of parts, milling, grinding, wire cutting, CNC, etc. are arranged. Treatment methods include quenching, anodizing, electroplating, painting and so on. After the parts are produced, they will be checked by the quality department. If they pass the check, they will be sent to next department. If they are not qualified, the parts will be reworked. The assembly will begin after the checking fixture parts are processed. The assembly personnel assemble the checking fixture parts according to the checking fixture design drawing/3D. Finally, the quality department does the overall assembly inspection and issues a qualified accuracy report.

There are many kinds of automotive checking fixtures, because each set of checking fixtures is non-standard customized, so if you want to do a good job in checking fixtures, you must constantly optimize the automotive checking fixture process.