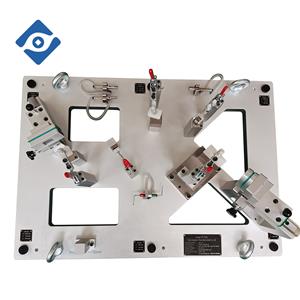

The function of CMM fixture

The function of CMM fixture

CMM fixture is a kind of auxiliary fixture when measuring parts with CMM. Its main function is to position parts and facilitate CMM measurement. All its supporting surfaces (points) and positioning datum surfaces (points) must be milled according to the CAD data of parts. Modern checking fixtures are often used as measuring fixtures in structural design. When the online inspection function of checking fixtures and CMM fixture function cannot be met at the same time, the online inspection function of checking fixtures should be met first.

Single-tube checking fixture for vent pipe

Qualitative and quantitative inspection of parts

In order to realize on-line inspection of parts, it is necessary to accurately install and position the parts on the checking fixture, and then check the key product characteristics (KPC) and key control characteristics (KCC) such as the part surface profile, peripheral trim line, function hole position, etc. by means of visual inspection, measuring meter or caliper, so as to quickly judge the size characteristics of parts, and the deviation between parts and CAD theoretical values can also be obtained by counting/digital display measuring tools.

FIFM Tips:

Key Product Characteristics = KPC , such as key and important dimensions, all the characteristics of the part itself.

Key Control Characteristics= KCC , such as equipment process parameters or key, important process process parameters.