Key points of welding fixture design dimensions

Key points of welding fixture design dimensions

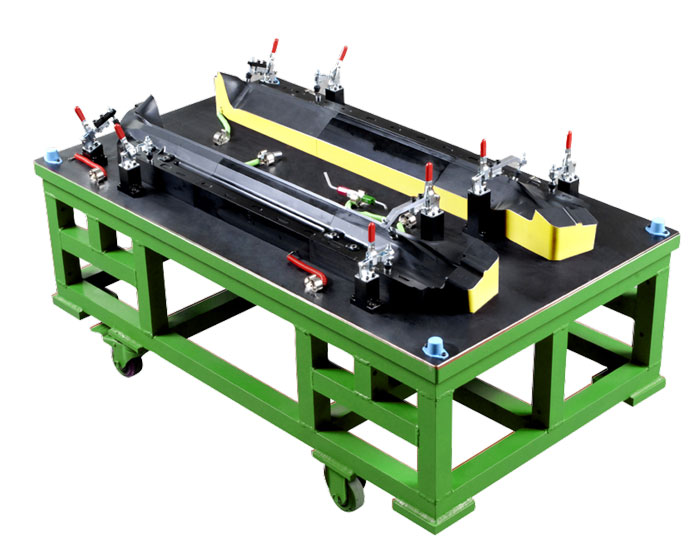

Safety first, conform to ergonomics.

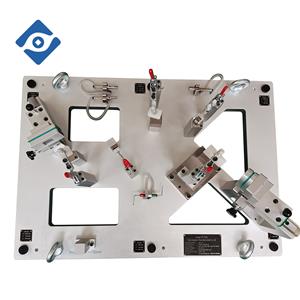

The positioning point is consistent with the drawing, and there is no interference with the parts, so that the parts can be placed for foolproof.

The measurement can be achieved, and the accuracy meets the enterprise standard.

The positioning pin is 3-5mm beyond the surface of the part, preferably a fixed pin or a taper spring pin.

The pressing force of the block is greater than 50KG to meet the welding requirements.

To prevent the pressure head from being too tight, a Stop Block will be set at the pressure arm.

The supporting surface shall be 20X20mm as far as possible, and its adjustment direction shall be consistent with the car body coordinate system.

Get the latest price? We'll respond as soon as possible(within 12 hours)

more products

News

Products

Featured Products

Contact Details