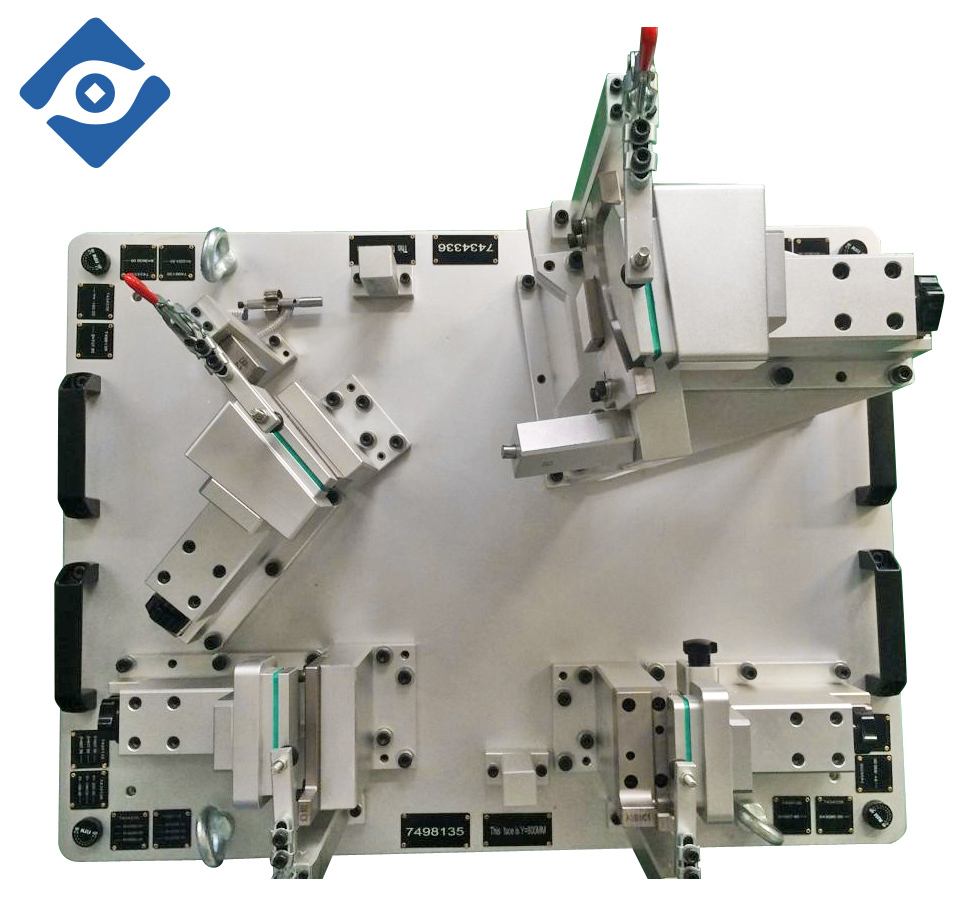

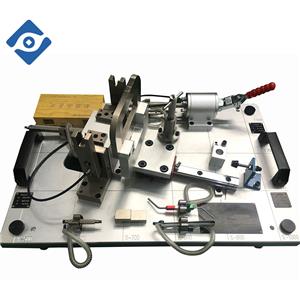

Design of taper pin for automobile inspection tool

Design of taper pin for automobile inspection tool

The taper pin of the automobile inspection tool is the main and auxiliary positioning pin of the general inspection tool, which can meet the general positioning of the product, and can guarantee the principle of freedom, that is, it can be positioned no matter how the hole size is changed, which is also the advantage of the taper pin positioning.

The design of the taper pin of the automobile inspection tool should ensure the angle of the taper pin. Generally, our design principle is 15° or according to the size of the product hole: the big end is the product hole +1, and the small end is the product hole -1.

The design of the taper pin of the automobile inspection tool should fully simulate the trajectory of the taper pin running up and down, to ensure that the taper pin can also be positioned when the product hole goes to the upper and lower limit deviations, and does not interfere with the inspection tool body.

The design of the taper pin of the automobile inspection tool should refer to the type of the product. For example, when the thickness of the product is too thin or there is no net around the datum hole, we should consider not to use the taper pin, because the taper pin will deform the product and affect the detection. In general, when the material of plastic parts is too soft, we should also consider the above problems.

The design of the taper pin of the automobile inspection tool does not need to consider the maximum entity principle marked on the drawing, because the taper pin is not affected by the size of the hole, and always locates the center of the hole of the product.