GO-NOGO regulations for automobile inspection tools

GO-NOGO regulations for automobile inspection tools

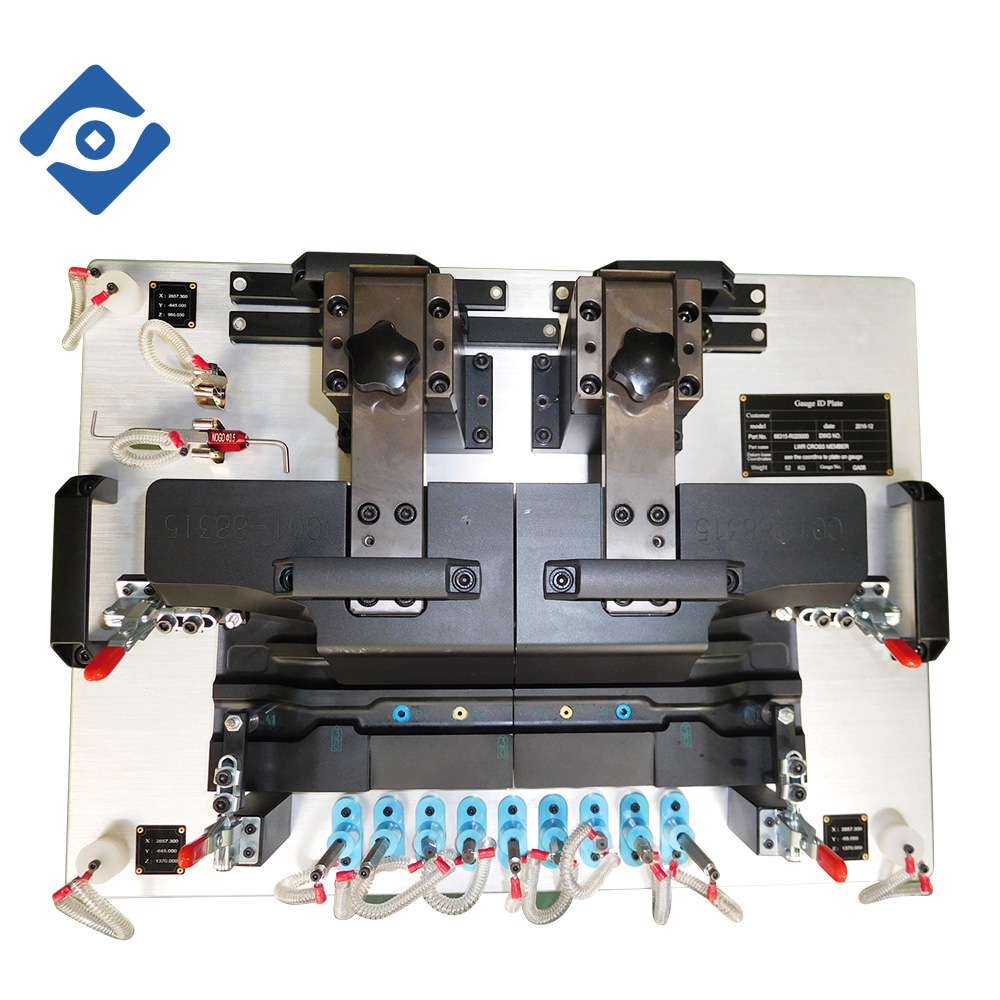

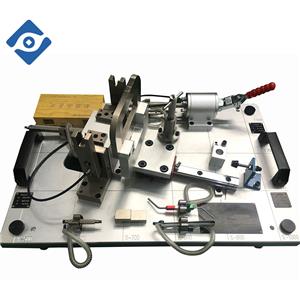

The GO-NOGO gauge is a measuring tool on the automobile inspection tool. Generally, we make a standard gap for the inspection tool to check the surface profile and trimming of the product. When checking, if the GO side can pass through, and the NO-GO side can not, then the part is OK, otherwise NG.

The size of the GO-NOGO gauge of the automobile inspection tool is determined by the tolerance of the product. We generally check the surface profile tolerance of the product through the drawings. For example, the profile tolerance of the product is +/-0.5, and the check gap of the inspection tool is 3.0, then the size of our GO-NOGO gauge is 2.5 at the GO side and 3.5 at the NO-GO side.

The production tolerance of the GO-NOGO gauge of automobile inspection tools is generally set to +0.02/0 of GO side and the set to 0/-0.02 of the NO-GO side. The reason why the standard of GO-NOGO gauge of automobile inspection tools is set is that our parts there will be errors in processing, but we should try to avoid the influence of these tolerances on detection when designing part tolerances, and even if they cannot be avoided, the minimum error should be reduced.

The GO-NOGO gauge includes the gap checking gauge and the aperture checking gauge. Although this is a two-position inspection, their production standards are the same.

The GO-NOGO standard for automobile inspection tools is one of the design standards for inspection tools. It is the basis and basis for us to design the GO-NOGO regulations for automobile inspection tools. In our daily design, we must refer to the standard to reduce errors.