The development of checking fixtures

The development of checking fixtures

In the past, there was only mold industry, no checking fixture industry. However, for products produced by molds, conventional measuring tools cannot be checked, and special checking fixtures must be used to control product quality. Therefore, have the mold industry must also have the checking fixture industry, otherwise the product produced by the mold cannot be guaranteed to be a correct and qualified product. As an example, if a car door is found to be unable to be installed during installation, and there is no checking fixture, the workers will knock on the door according to their own ideas, change its shape and install it. There are considerable hidden dangers in the safety of the rear; after the checking fixture is available, the door is placed on the professional checking fixture for inspection, and the areas that do not meet the standards can be rectified to achieve the exact same specifications as the factory.

The rapid development of modern industry has promoted the continuous improvement of the production efficiency of automobile production lines. Today, an entire vehicle can be installed in an average of 8 minutes on the vehicle assembly line. A car has thousands of parts, and its body has more than 300 sheet metal parts and more than 100 plastic parts. If there is a problem with one or two parts, it is very likely that the whole car will fail to assemble. Therefore, to ensure that each component is fully up to standard at the beginning of the assembly line, checking fixtures are required. For car manufacturers, every minute of downtime means the loss of real money. Therefore, in order to rapidly develop the automobile industry and reduce the cost of automobile manufacturing, automobile manufacturers must introduce checking fixtures to improve the standardization and automation of production.

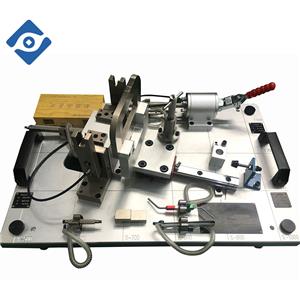

As we all know, automobile manufacturers have a variety of models. The lights, doors, hoods, bumpers, rearview mirrors and even the body of each car are different. Whether these parts and components have manufacturing errors and whether they meet the design standards? All have to rely on car checking fixtures to check. The so-called automobile checking fixture refers to a special checking fixture directly used to inspect and measure the size, shape and position characteristics of automobile parts.

Automobile checking fixtures are equivalent to third-party certification tools for auto parts companies and vehicle manufacturers. After the initial production of auto parts is completed, they are placed on special automobile checking fixtures for testing. Only qualified parts can enter the next step in the production process, otherwise, the auto parts need to be improved and processed until they fully meet the design requirements, which can ensure the smooth flow of the entire production line. Therefore, the automobile checking fixture can improve the machining accuracy and production efficiency of auto parts companies and vehicle manufacturers, and effectively solve the problems of coordination between auto parts and the design consistency of the whole vehicle.

Our company undertakes various non-standard/custom part automotive checking fixtures, design and manufacture automotive interior and exterior trim parts checking fixtures and various sheet metal parts/plastic parts checking fixtures. With excellent quality, punctual delivery and perfect service, it has been well received and recognized by domestic and foreign customers. Adhering to the business philosophy of integrity, doing things with the heart, customer-oriented, creating a win-win situation, creating automotive checking fixtures and industry fields!