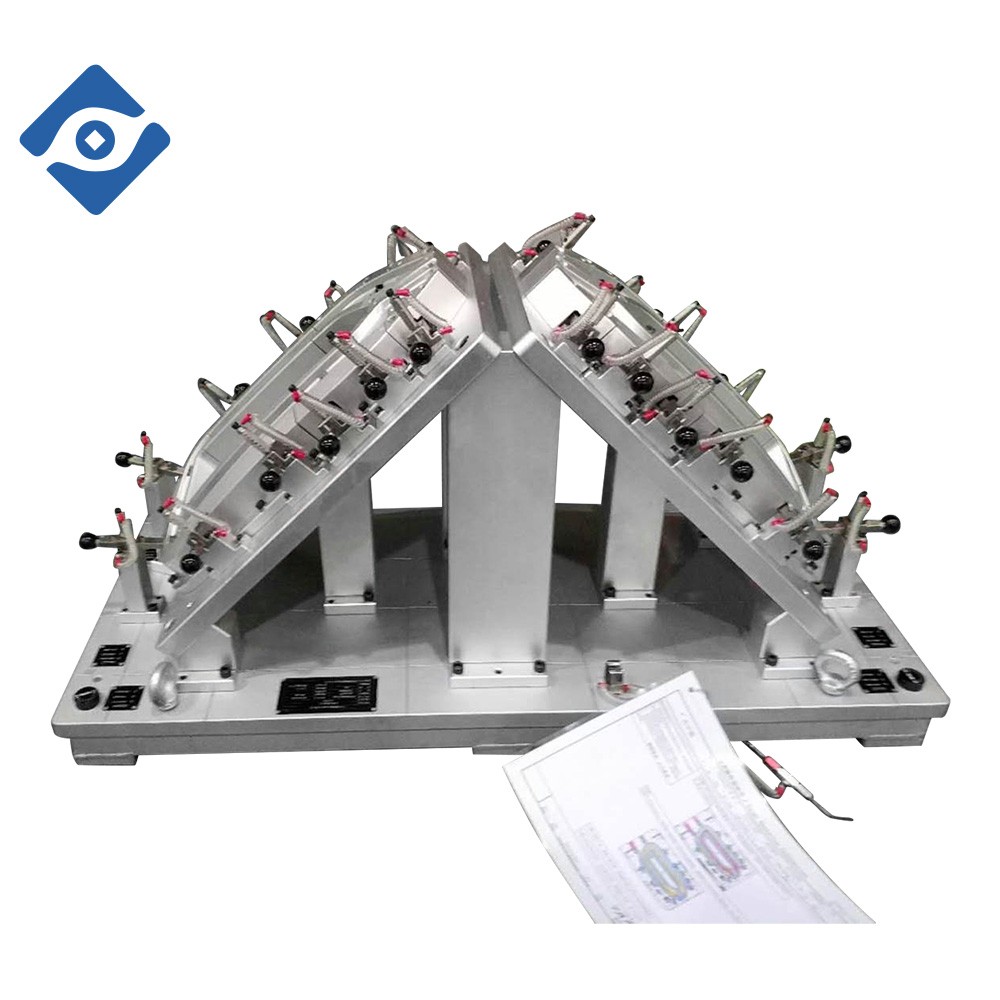

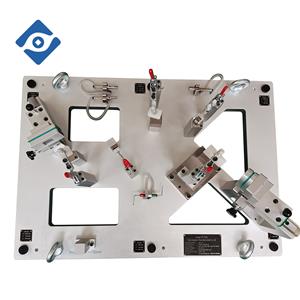

Checking Fixture For Frame Tail Lamp

- FIFM

- CHINA

- 30 working days

- 800 sets/year

Gauge type: Checking Fixture for plastic part

Inspection type: hole position, hole size, surface profile and trim edge,flatness check,CMM inspection

Checking Fixture For Frame Tail Lamp

Checking fixture

It is a special inspection equipment used to measure and evaluate the dimensional quality of parts;

It is a special fixture specially manufactured according to the specific requirements of the demander, which is directly used to inspect the part size, shape/profile, and position characteristics;

It is a special inspection equipment for online inspection of stamping parts, metal parts and welding parts;

It is a special inspection tool designed and made to facilitate inspection of quality, improve production efficiency, control product quality uniformity, reduce cost, and eliminate the influence of human factors on products during mass production.

Measuring jig

It is an auxiliary bracket when measuring parts with CMM. All supporting surfaces (points) and positioning datum surfaces (points) must be milled according to the CAD data of the part. The measuring bracket of some special parts should also have the function of part of the car checking fixture.

Automobile checking fixtures and measuring jigs can reasonably measure the geometric parameters of parts according to valid product drawings and CAD data. With the help of three-coordinate measuring machine(CMM), the automobile checking fixtures and measuring jigs can be verified and appraised.

Milling machine/grinding machine/CNC

CMM measurement

Assembly