Checking fixture for auto HALTER ZELLMODUL

- FIFM

- CHINA

- 30 working days

- 800 sets/year

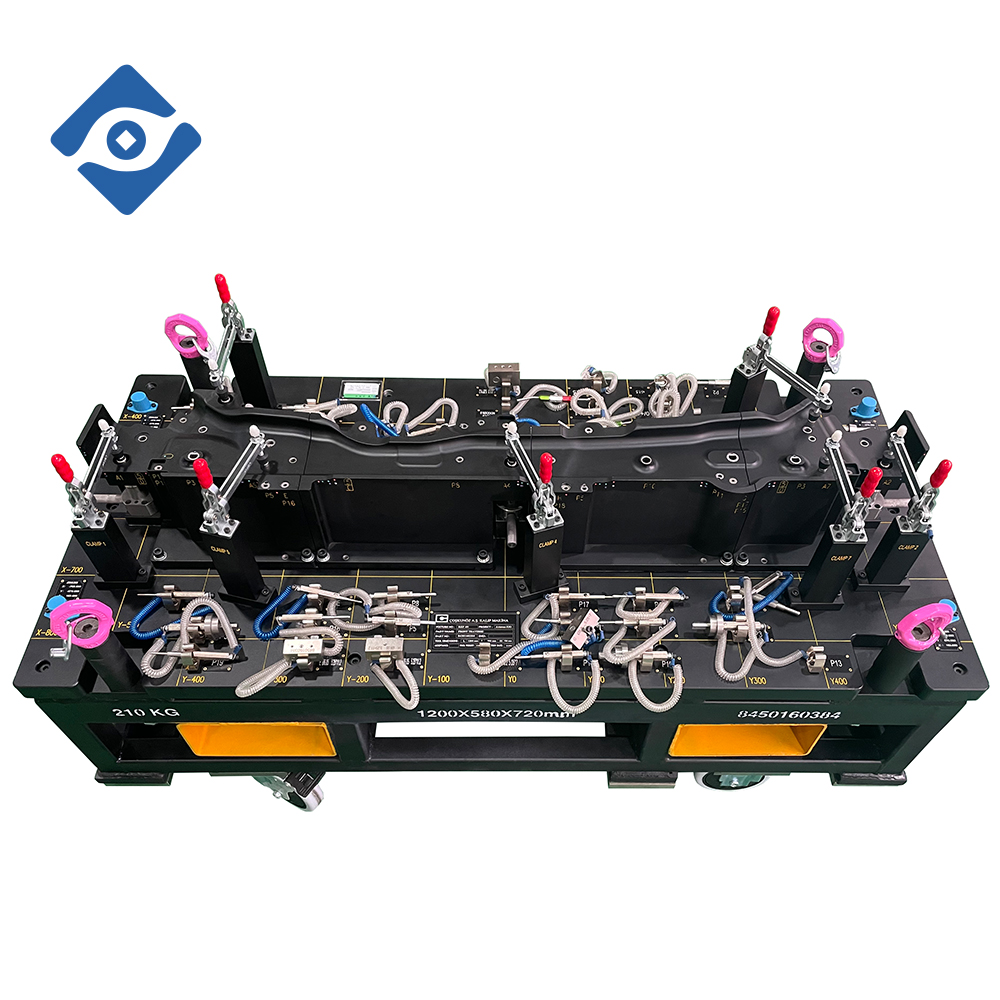

Checking fixture for auto HALTER ZELLMODUL

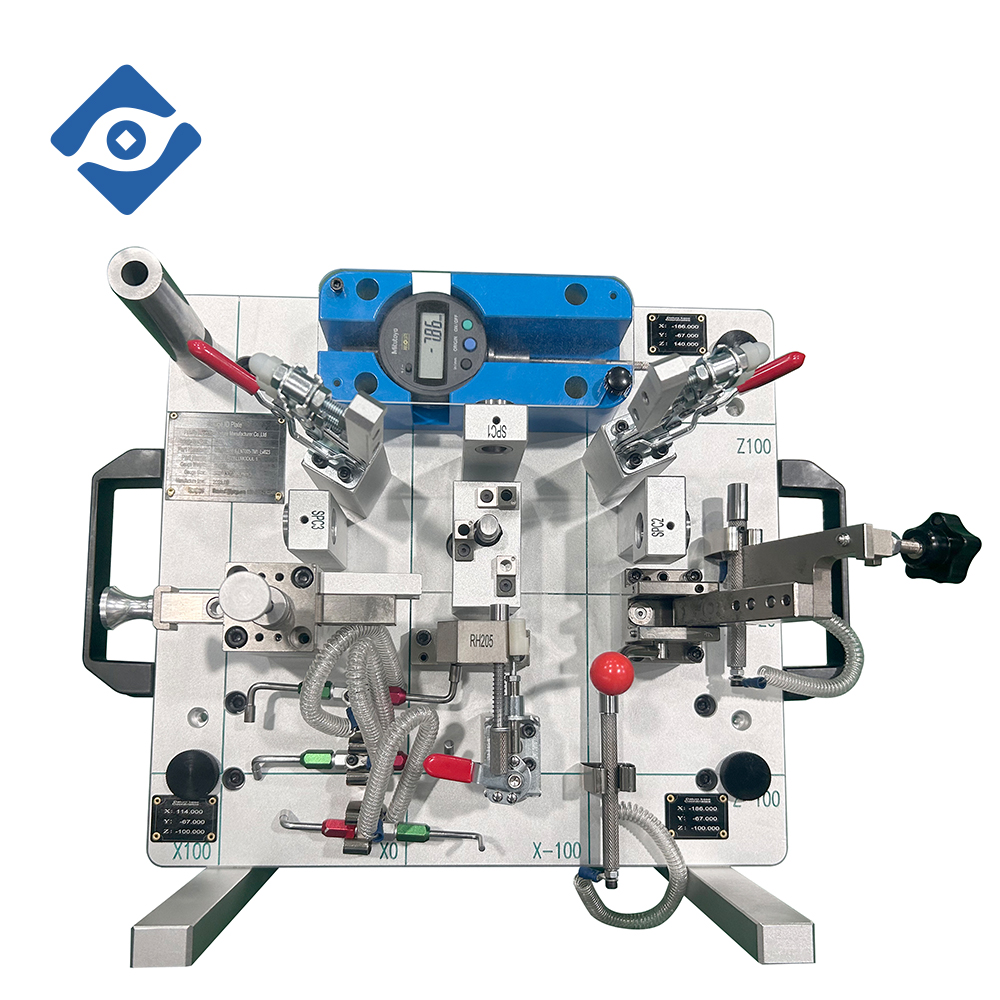

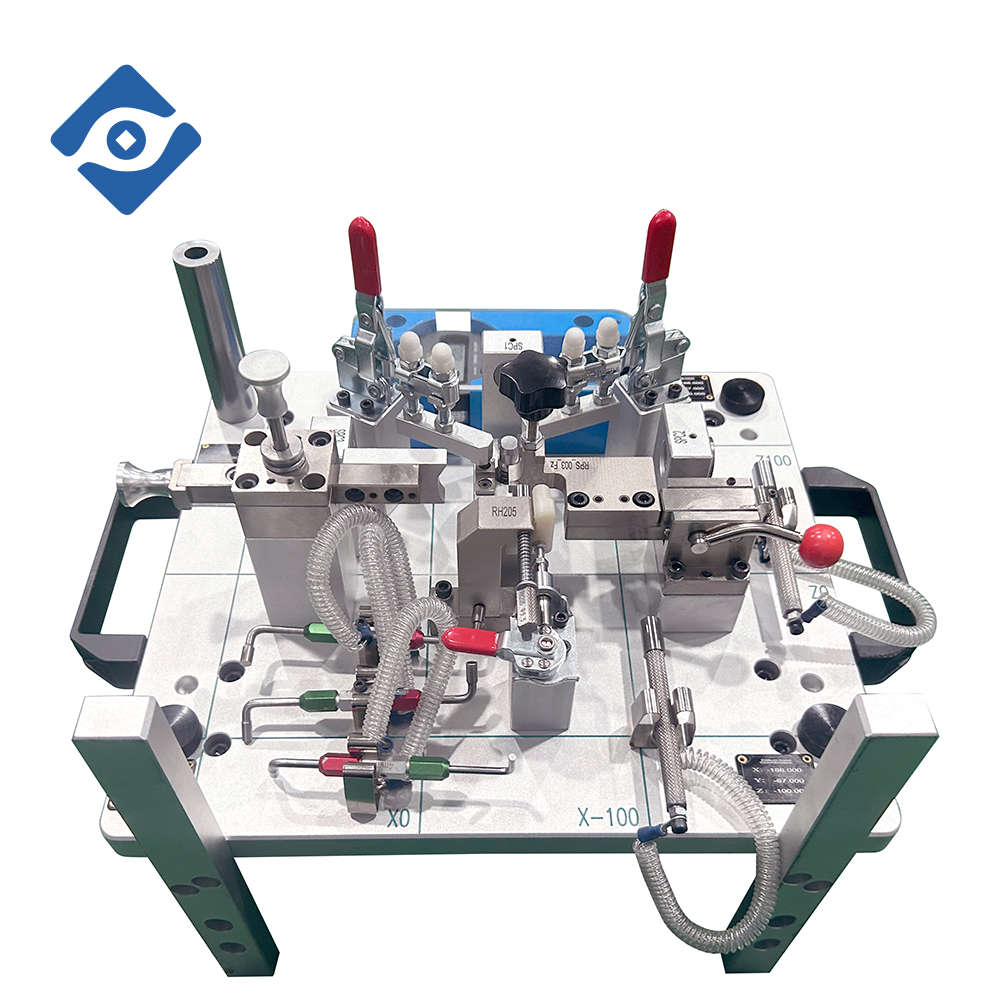

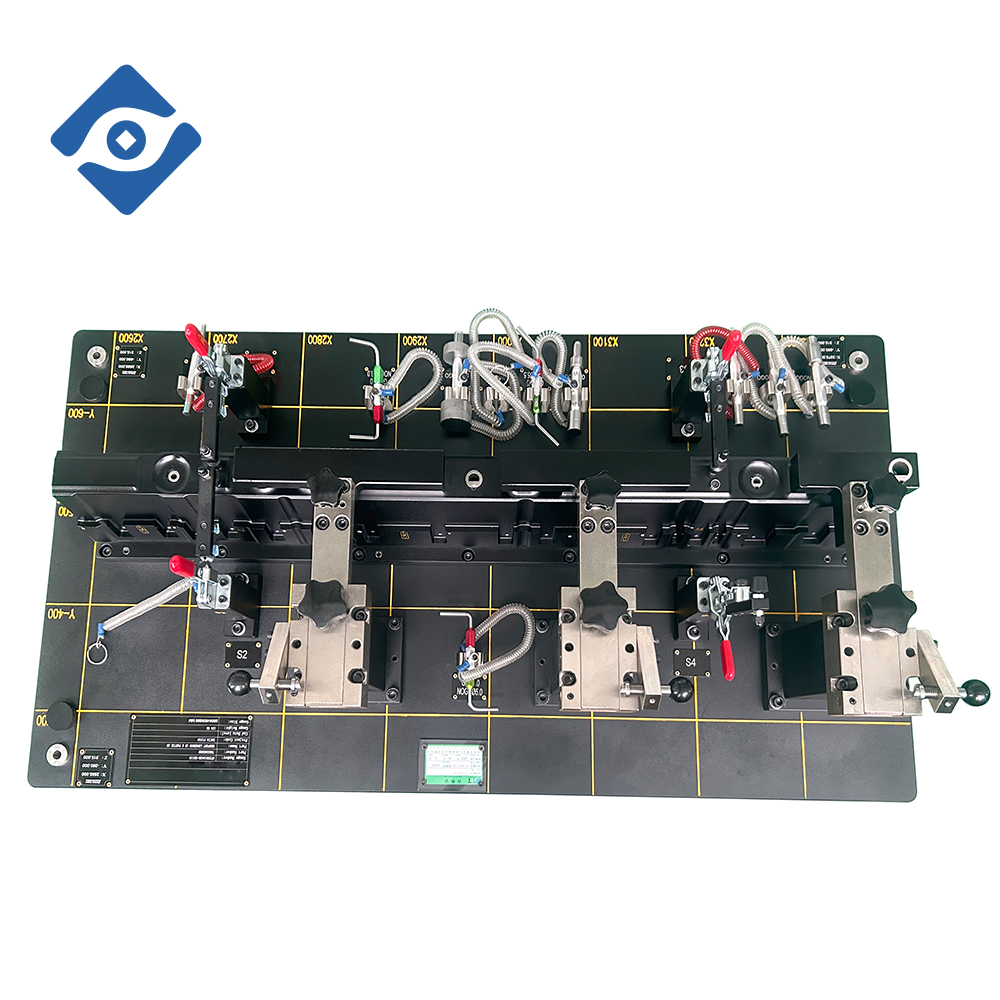

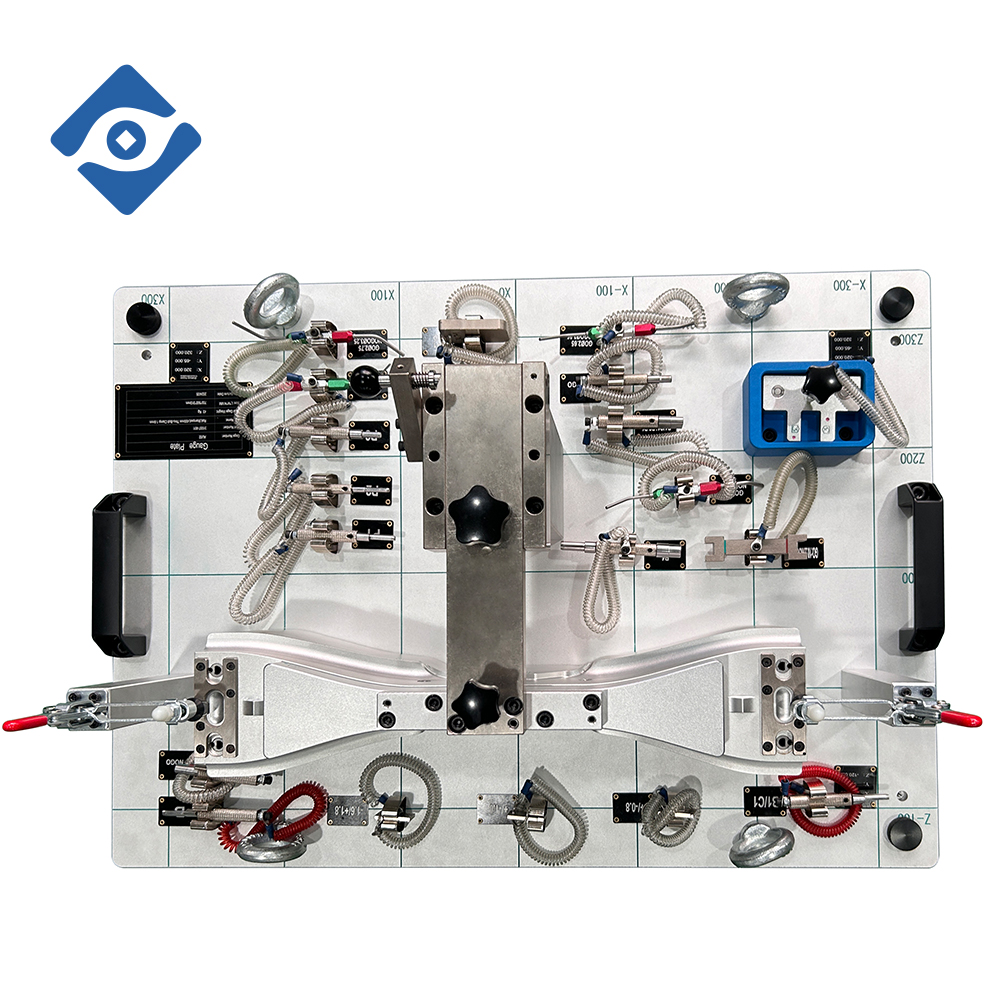

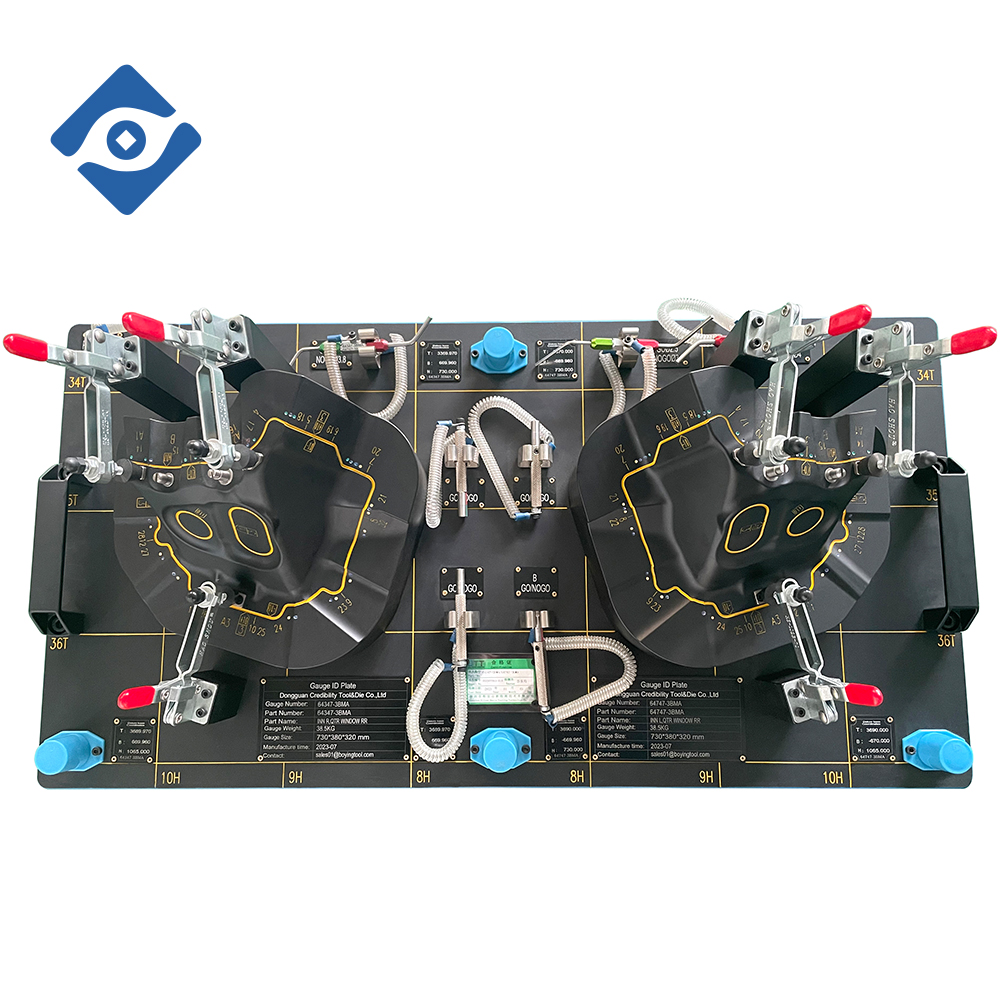

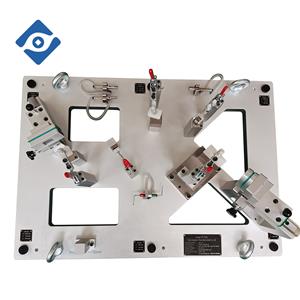

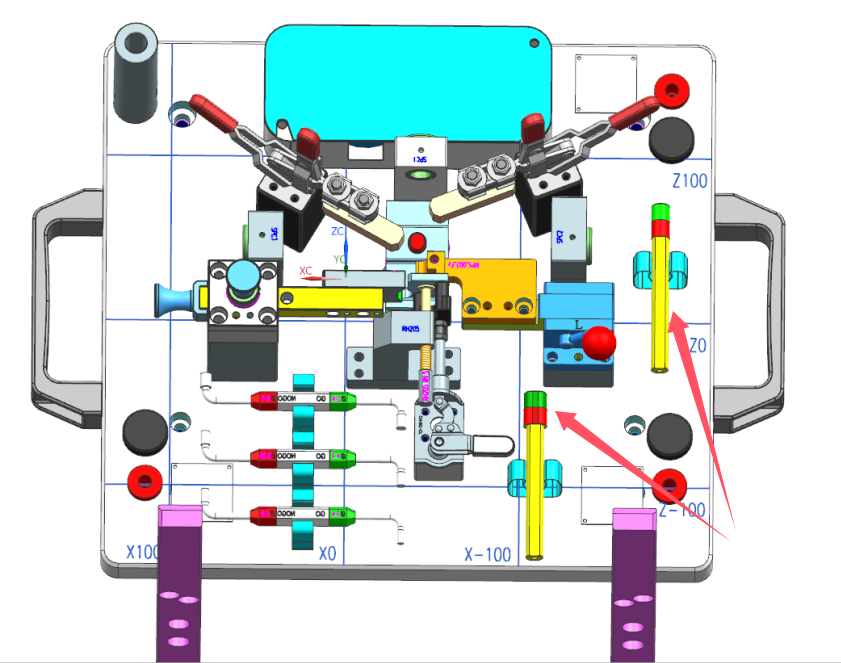

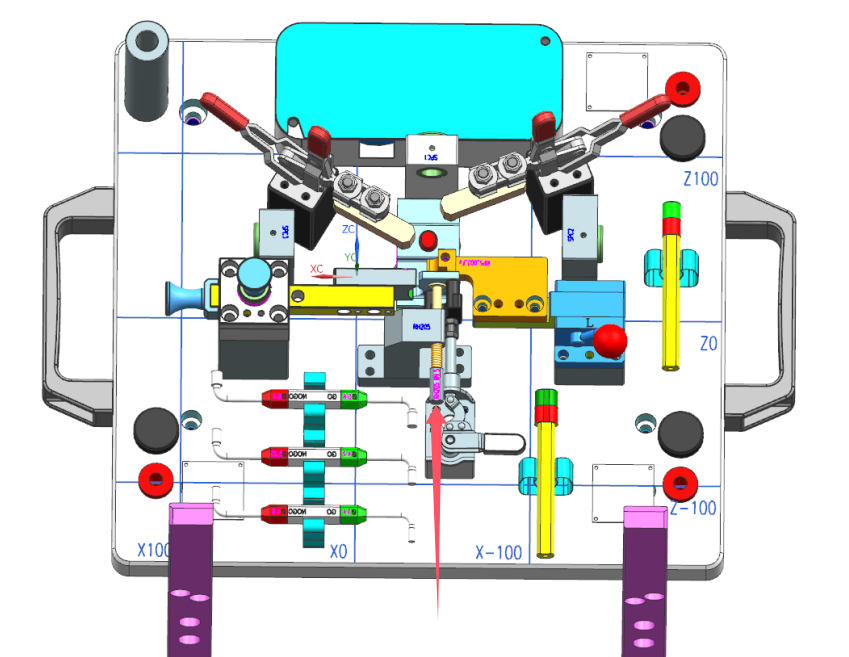

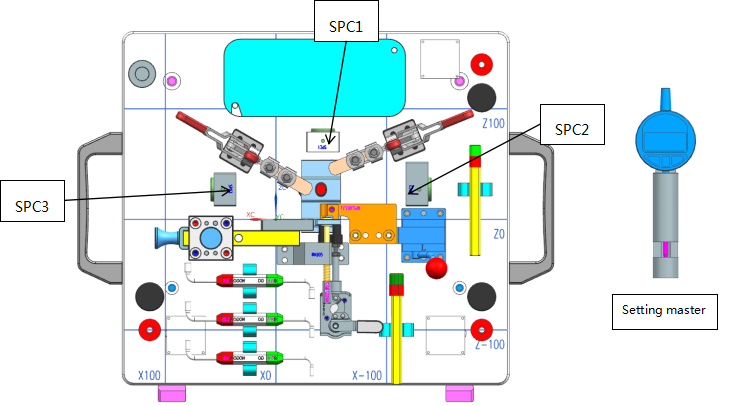

type: checking fixture

Scope of checking: Hole size, Hole position, surface profile and SPC check

Checking fixture for auto HALTER ZELLMODUL

Check the hole size, hole position, profile and SPC point according to customer requirements.

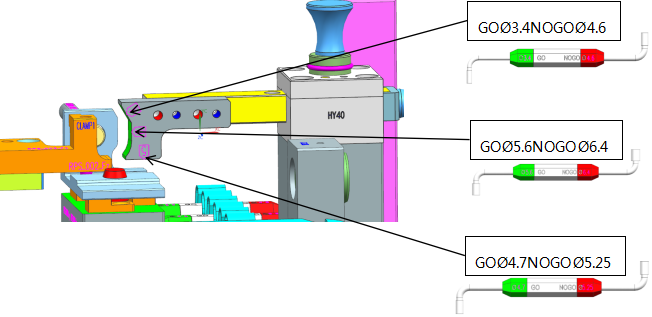

1.Hole Diameter GO/NOGO Detecting the Hole Size of Parts.

2. Put the part on fixture, locating the part base on the datum.

3. Check the hole position of part.

4. Use relative GO/NOGO check the part profile.

5. Use dial gauge to check the SPC points of part.

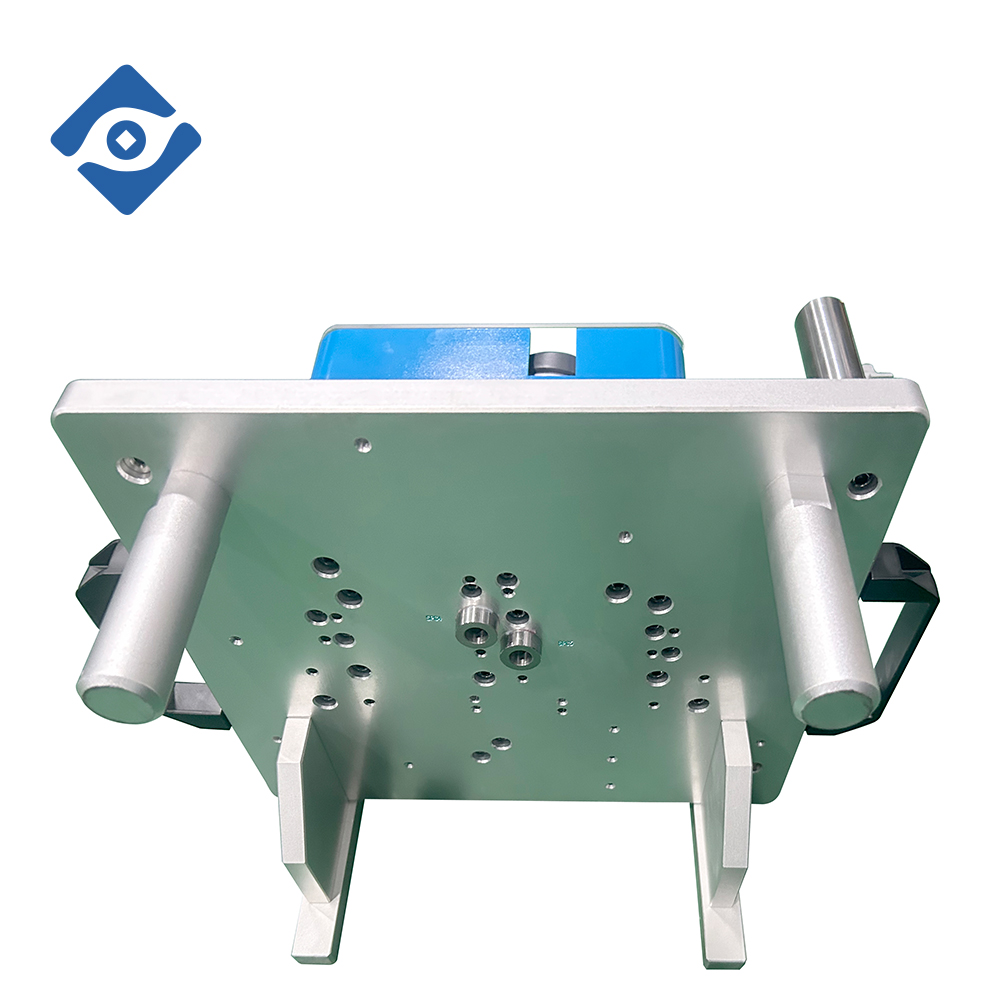

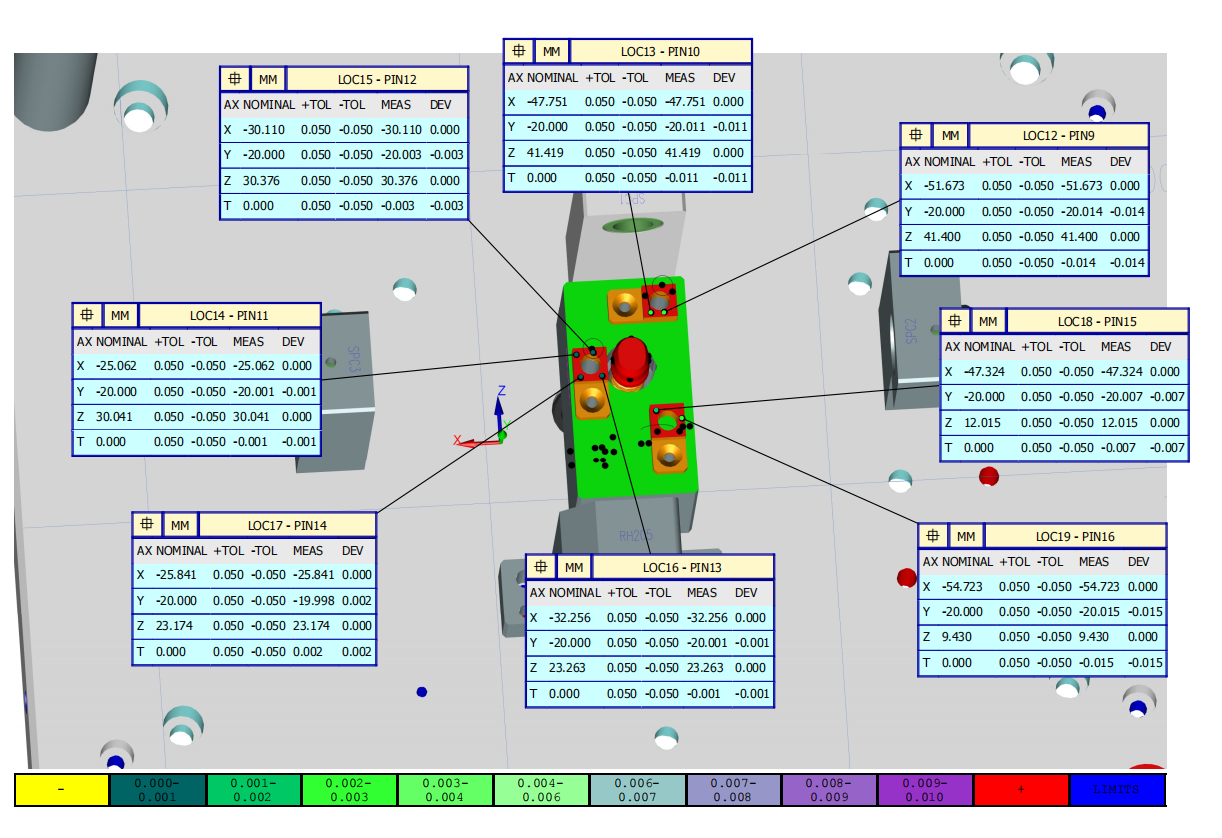

The fixture will verify the accuracy on CMM before assembly. Take the Net surface as an example.

If necessary, it also can be sent to a third party for certification.

We can make customized fixtures and services for you. If you are interested, please feel free to contact fifmsales08@fgauge.com