How to use the step gauge in auto checking fixture?

How to use the step gauge in auto checking fixture?

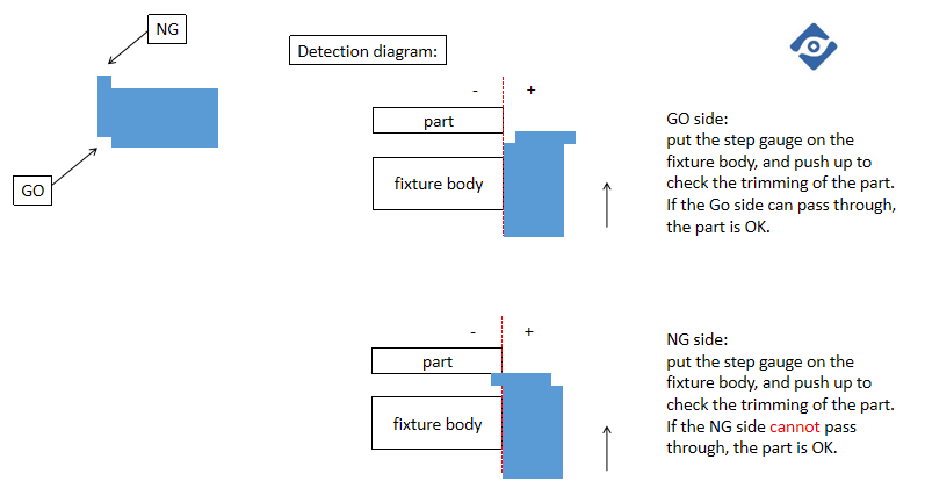

To know how to use the step gauge, we must first know what the step gauge is. The step gauge is a tool for checking the trimming of the part, which is used to detect when the part is trimmed or the surface is trimmed.

The design of the step gauge is based on the tolerance of the surface or edge to be checked.

Common step gauge forms are as follows:

The picture above shows the general method of using step gauges in automobile checking fixtures.

The step gauge is only used when the checking fixture is trimmed or the surface is trimmed. Generally, the step gauge is not used when the trimming is used for scribing detection.

If a step gauge is used, attention must be paid to the flatness of the surface in the design of the flush face in the early stage. If the flush face is arc-shaped, it will affect the result of the flush gauge detection.

When using the step gauge, the design of the front trim surface must pay attention to the flatness of the surface. If the trim surface is arc-shaped, it will affect the test result of the step gauge.![]()