Do automotive checking fixtures require CNC processing?

Do automotive checking fixtures require CNC processing?

Production and manufacturing are an essential part of social industry, and parts processing is naturally indispensable in the manufacturing industry. The need for CNC processing has become the mainstream, and many parts are processed using CNC equipment. Therefore, some people may ask whether automotive inspection tool/checking fixtures require CNC processing. The answer is yes.

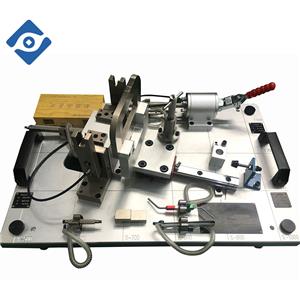

In the current automotive parts manufacturing industry, there is an increasing demand for the use of inspection tool/checking fixtures. As a commonly used tool in the production process of automotive parts, the requirements for automotive inspection tool/checking fixtures themselves are also very high. From the processing of various parts of the inspection tool/checking fixture to assembly, and then to the adjustment and confirmation of accuracy, every step must be taken seriously.

Automobile inspection tool/checking fixtures are assembled from many parts, and each part may have different shapes and functions, and the processing equipment used may also be different. The body of automobile inspection tool/checking fixtures is most processed using CNC, because the body of automobile inspection tool/checking fixtures generally needs to be consistent with the 3D surface of the product, and the 3D surface processing cannot be separated from CNC. Therefore, automobile inspection tool/checking fixtures require CNC processing and are essential. The processing of other parts of automotive inspection tool/checking fixtures also involves the use of grinding machines, milling machines, or other equipment due to the shape and function of the parts. The above content provides a simple explanation for the processing of automotive inspection tool/checking fixtures. From the above content, we can also obtain a positive answer that automotive inspection tool/checking fixtures require CNC processing.

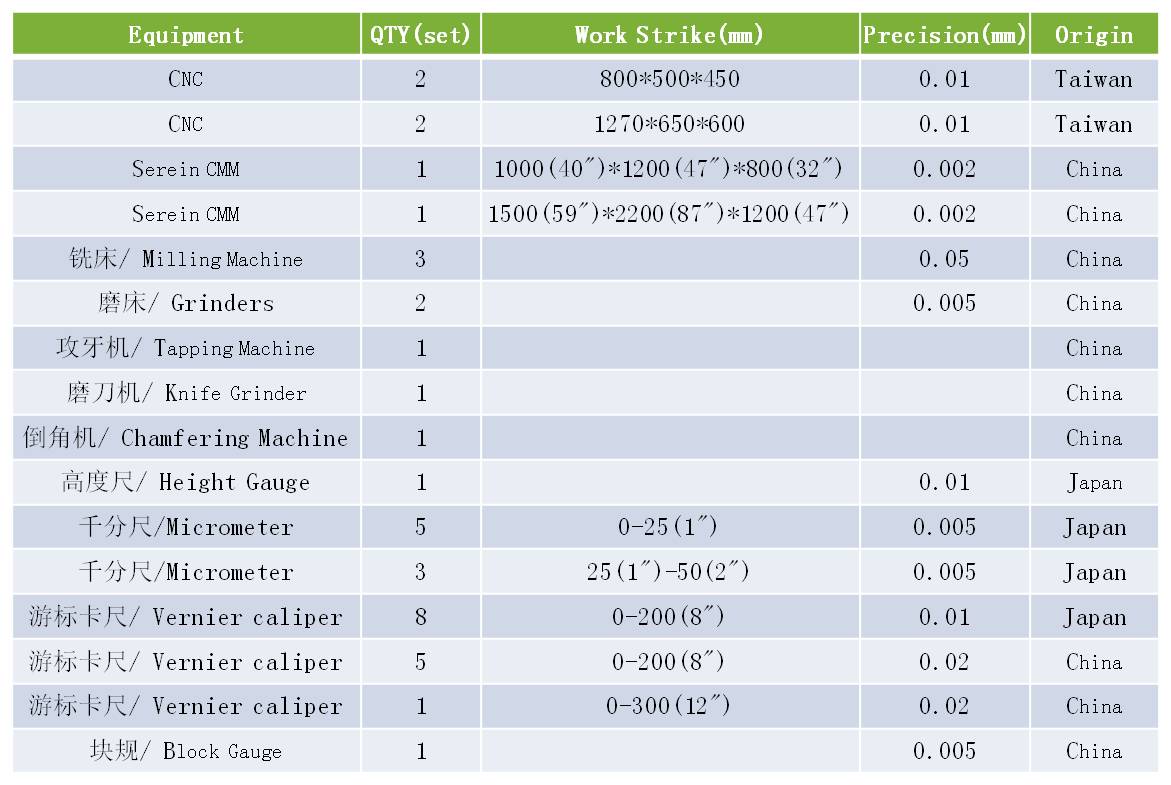

The following is our equipment list: