Design Concept of Automotive Checking Fixture --- Modeling

Design Concept of Automotive Checking Fixture

--- Modeling

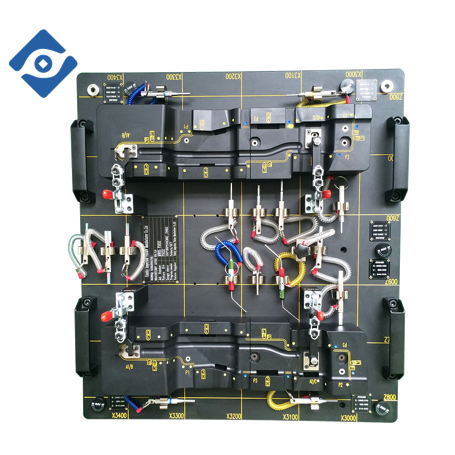

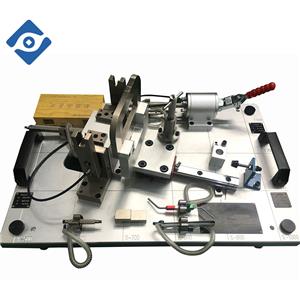

First of all, it is necessary to refer to the part drawing (GD&T) and 3D CAD analysis, initially formulate the design of the checking fixture, determine the datum surface/concave and convex conditions of the checking fixture, and check the cross-section and positioning surface.

In the design of automobile checking fixtures, the design modeling of fixture body is the key, which directly affects whether the checking fixture can accurately check the quality of the part.

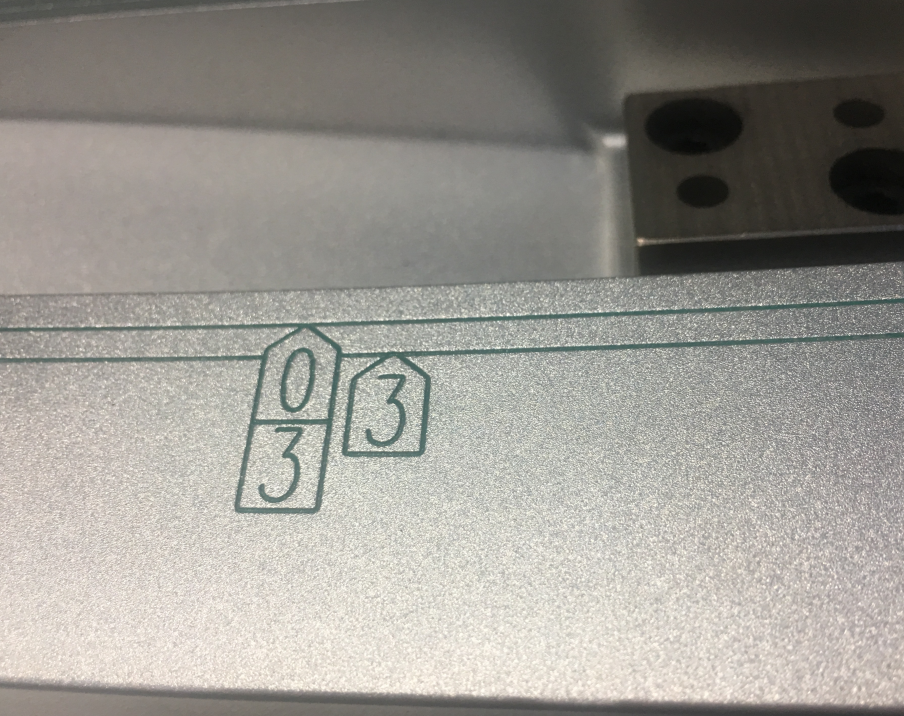

To realize the checking of the free-form surface of the part by the checking fixture, generally keep a constant gap of 3 or 5mm between the surface of the fixture body and the inner surface of the part. In the actual checking, the deviation of the part surface can be measured by the profile of the checking fixture with the special measuring tool.

There are two main checking methods for the outer contour/profile of the part. When designing the corresponding checking fixture: ① the checking surface extends tangentially outward about 20mm along the outer contour of the part; ② extends down about 20mm along the normal direction of the outer contour of the part. In general CAD software (such as UG), offset the part surface by a distance of 3 or 5mm inward , and then put the surface along the tangential or normal direction of the contour is extended by 20mm to obtain the specific checking body surface, and then stretched to the datum surface for a certain distance is the checking fixture body model.

Due to the complexity of the car body cover, the combination of the above two methods is mostly required when generating the checking fixture body surface, but for some special profiles, this is still difficult to achieve. For complex profiles, if the part surface of the inner engine support has two obvious self-intersections and interferences, in order to ensure that the main contour of the part can be checked, it is necessary to sacrifice the checking at the corners with vertical height difference, and generate checking fixture body surface. Finally, make a 3mm double scribe along the contour and gap of the part on the checking fixture body surface, so as to facilitate the checking of the contour of the part. Of course, many similar problems will be encountered in the design of checking fixtures (especially checking fixture body), and post-processing needs to be carried out on the penetration understanding and experience of checking fixtures.