Correlation between automobile checking fixture and automobile mould

Correlation between automobile checking fixture and automobile mould

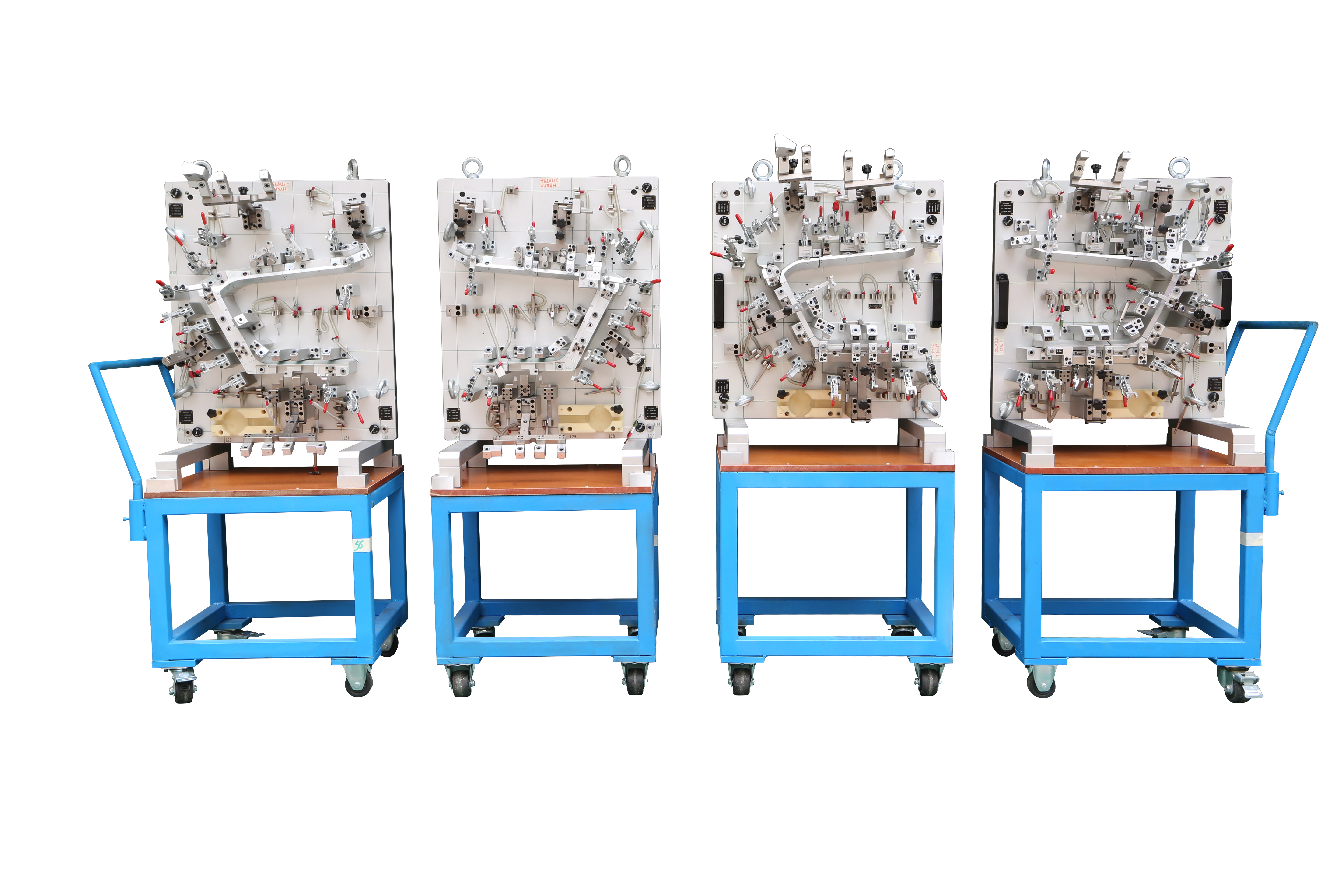

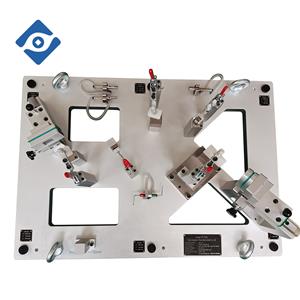

Because of its simple structure, convenient use and lower manufacturing cost compared with other measuring technology tools, so it has been widely used. Especially when the tolerance of parts in automobile parts is relatively large, and there are many errors in the manufacturing process, the checking fixture is widely used in automobile parts and automobile mold field with its unique advantages. It is not the purpose of simply using the checking fixture to judge whether the part is qualified, but more of all, it is to find out the quality problems by analyzing the measured data, and provide reliable basis for the improvement of production and processing technology, so as to achieve the purpose of ensuring and improving the part quality.

There is a certain relationship between automobile checking fixtures and automobile molds. They serve the parts together, the parts originate from molds, and the checking fixtures check the parts. As the China saying goes,"Nothing can be accomplished without norms or standards". Molds are the "norms". The structure and precision of the molds themselves and the technological parameters in production determine the dimensional accuracy and surface quality of the parts. However, "whether it is accomplished" can be understood as the ability to make a part accomplish with a checking fixture. That is, whether the shape and size of the produced parts meet the requirements? It can't be judged by a mold that just a manufacturing tool. We can't say "the size of our parts is guaranteed by the mold". The qualified dimensions of parts need to be determined by measuring tools or checking fixtures, especially in mass production.

Therefore, the checking fixture is a special inspection tool used to measure and evaluate the size and quality of parts, which plays an important role in the quality control of parts. The automobile checking fixture is as important as the automobile mold. There are many kinds of automobile parts, and the size matching requirements of related parts are high. The part development and quality workers of automobile parts should upgrade the design, manufacture and use of the checking fixture to the same important position of the mold.