Basic knowledge of checking fixture design

Basic knowledge of checking fixture design

A. the concept of car body coordinate system: the car body coordinate system is that it points to the rear of the car in X direction, to the right of the car in Y direction and to the roof in Z direction with the front point of the front axle center or the front bumper center as the origin.

B. GD&T (geometric dimensioning and tolerance) concept: refers to drawings describing the geometric dimensions and tolerances of parts. This drawing clearly reflects the positioning datum of specific parts, the theoretical dimensions and tolerances of the items to be checked, KPC( Key Product Characteristic) points, the size of positioning datum and other information. It is also one of the main basis for designing checking fixture. It involves concepts such as datum, size, elements, tolerance, form and position tolerance,etc.

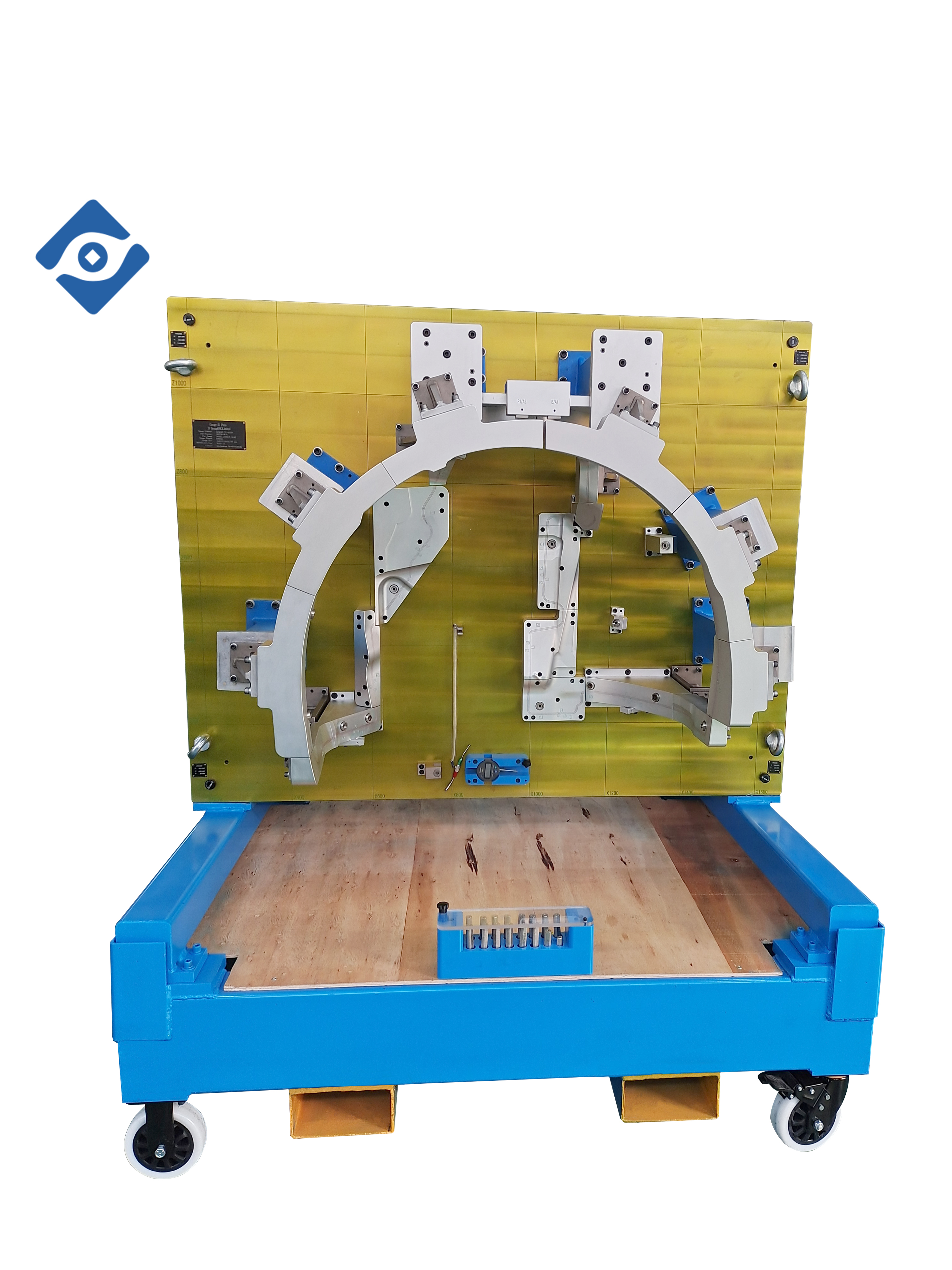

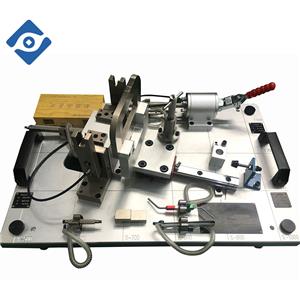

C. Concept of measuring sample frame/CMM fixture: In order to extract and check part characteristic data (by CMM), the testing bracket/fixture is generally designed and manufactured according to the body coordinate system. Its positioning datum should meet the requirements of GD&T drawing. At the same time, it must include datum surface or datum hole used to establish the precision of the measuring bracket/fixture itself. Shanghai Volkswagen often uses it. Generally speaking, it is the positioning and clamping part of the checking fixture.

D. Concepts of digital model/3D, sample and surrounding part:

Digital model/3D : it is a three-dimensional mathematical model constructed by part design department or automobile factory according to body coordinate system or user coordinate system. It is the theoretical size of the part.

Sample: it is a qualified part provided by the customer and used as the standard for subsequent development. If the fixture is designed according to the sample, it is required that the sample must be unique, and the sample must be labeled and properly kept. Because there is a certain deviation between qualified parts and theoretical parts, although this deviation meets the part tolerance requirements, the deviation of each qualified part is different, so it is reasonable to require only one sample. The uniqueness of the sample requires it to be properly kept to avoid the deformation and aging of the product caused by sun, rain and temperature difference.

surrounding part: refer to parts that have assembly relationship or matching relationship with parts.

E. Concept of fixture pattern book and checking standard/datum book: fixture pattern book refers to the preliminary design concept of fixture, which basically reflects the positioning standard/datum, inspection method and basic structure of checking fixture. It is generally used to communicate and confirm the fixture design scheme with customers before formal fixture design. Checking standard book refers to the inspection specifications of parts, including the inspection of all dimensions and performance of parts. The fixture design must meet the requirements of fixture pattern book and checking standard book. *The concept of pattern book and checking standard book is generally only reflected in the Japanese car.

F. Certification process of checking fixture: Due to special reasons that checking fixture directly affects product quality, regular car manufacturers will certify the design and manufacture of checking fixture.