The purpose of the checking fixture

The purpose of the checking fixture

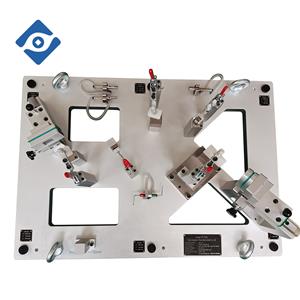

The checking fixture is a special inspection equipment used to measure and evaluate the size and quality of parts. It is a simple tool used by industrial production enterprises to control product dimensions (such as hole diameter, space size, etc.) to improve production efficiency and control quality. Mass-produced products (such as auto parts) to replace professional measurement tools (such as calipers, micrometers, CMM).

micrometers

At the production site of parts, the online inspection of parts is realized through the automobile checking fixture. For this purpose, the parts need to be accurately installed on the checking fixture, and then the part surface profile and trim edge can be inspected by visual inspection, or dial gauge, or caliper. With the help of checking pins or visual inspection, to check holes of different natures on parts and the connection position between parts and parts, so as to realize the judgment of the quality status of the parts during trial production and start-up production. In this case, it can be judged by visual inspection or measurement: the deviation between the surface profile and trim edge size and shape area of the part contour and the relative position and the theoretical value of the checking fixture directly processed by CAD/CAM.

For some important functional dimensions on the part, the checking fixture can also be used for numerical inspection. Usually, the coordinate value of the part based on the body coordinate system cannot be directly obtained with the aid of the checking fixture, but can be obtained by placing the part on the checking fixture and measuring it with a three-coordinate measuring machine(CMM). The structure of modern checking fixtures is designed with the consideration that it can be used as a measuring bracket/jig. However, when the online inspection function of the checking fixture and the function of the measuring bracket/jig cannot be satisfied at the same time, the online inspection function of the checking fixture should be satisfied first.

The measuring bracket/jig is an auxiliary bracket when using a three-coordinate measuring machine(CMM) to detect the three-coordinate of the measured parts. All its supporting surfaces (points) and positioning datum surfaces (points) must be milled according to the CAD data of the parts, and the measuring brackets/jig of some special parts should also have the function of some checking fixtures.

The checking fixture and the measuring bracket/jig can reasonably measure all the data of the part according to the product drawings and CAD data, and the checking fixture and the measuring bracket/jig can be checked and identified with the help of the three-coordinate measuring machine(CMM).