How wide is the technical field of automobile checking fixture?

How wide is the technical field of automobile checking fixture?

Speaking of cars, of course, everyone knows what it is, but about automobile checking fixture and there may be some people who don't quite understand it. When it comes to the technical field of car fixtures, it needs professionals to make it clear.

With the development of automobile fixture industry in recent years, the technical requirements of automobile fixture are getting higher and higher, and the technical requirements for employees are also rising. So what are the contents involved in the technical field of automobile fixture?

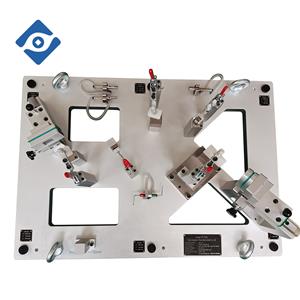

From the user's point of view, when a user gets a qualified automobile fixture, he needs to know which product the fixture is for the first time. At the same time, he also needs to identify some size requirements on the product drawings, that is, to read the drawings. Next, we need to know how to use the fixture. Usually, manufacturers will be equipped with instructions, that is, to understand the function of the fixture. The next step is to verify whether the product is qualified according to the steps in the operating instructions, which means the correct use.

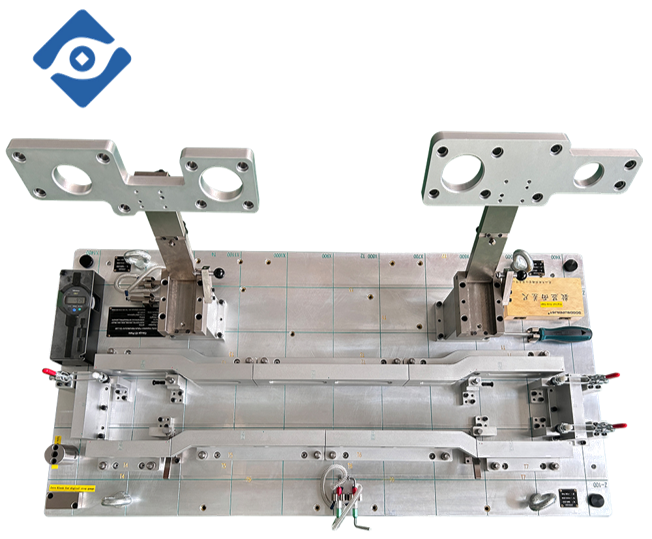

From the manufacturer's point of view, to make a good automobile inspection fixture, it is necessary to start from the design work first. As a design engineer, it is also necessary to digest and understand the relevant dimensional tolerances on the product drawings before the next design work can be carried out. It is also necessary to know the drawings first, and then make corresponding functional settings for the inspection fixture according to the tolerances on the product drawings to meet the inspection needs of the drawings. At this time, the engineering design should comprehensively consider the shape, structure, function and operability of the fixture, and make a targeted and feasible design scheme. The production department will process and produce according to the design drawings, as well as the subsequent three-coordinate and assembly work, all of which will be based on the design drawings to make a qualified fixture step by step.

Because the fixture itself is a testing tool, the requirements for the fixture itself are very high, so there will be various technical parameters involved. The technical field of automobile fixture may involve the application tolerance of engineering mechanics materials and the principle of complete machining. If you want to make a good fixture, you really need some ability to manufacture a qualified automobile part fixture.