How to process automotive checking fixtures generally?

How to process automotive checking fixtures generally?

With the development of the Chinese automotive market, automotive inspection tools have become one of the essential tools in the automotive industry chain.

Especially in recent years, with the continuous increase of automobile inspection tool manufacturers and the rapid development of the inspection tool industry chain, the supply of raw materials to standard parts, as well as the processing technology of inspection tools, have been continuously optimized in the industry. Non standard parts are basically produced by machining, so how do automobile inspection tools generally be processed?

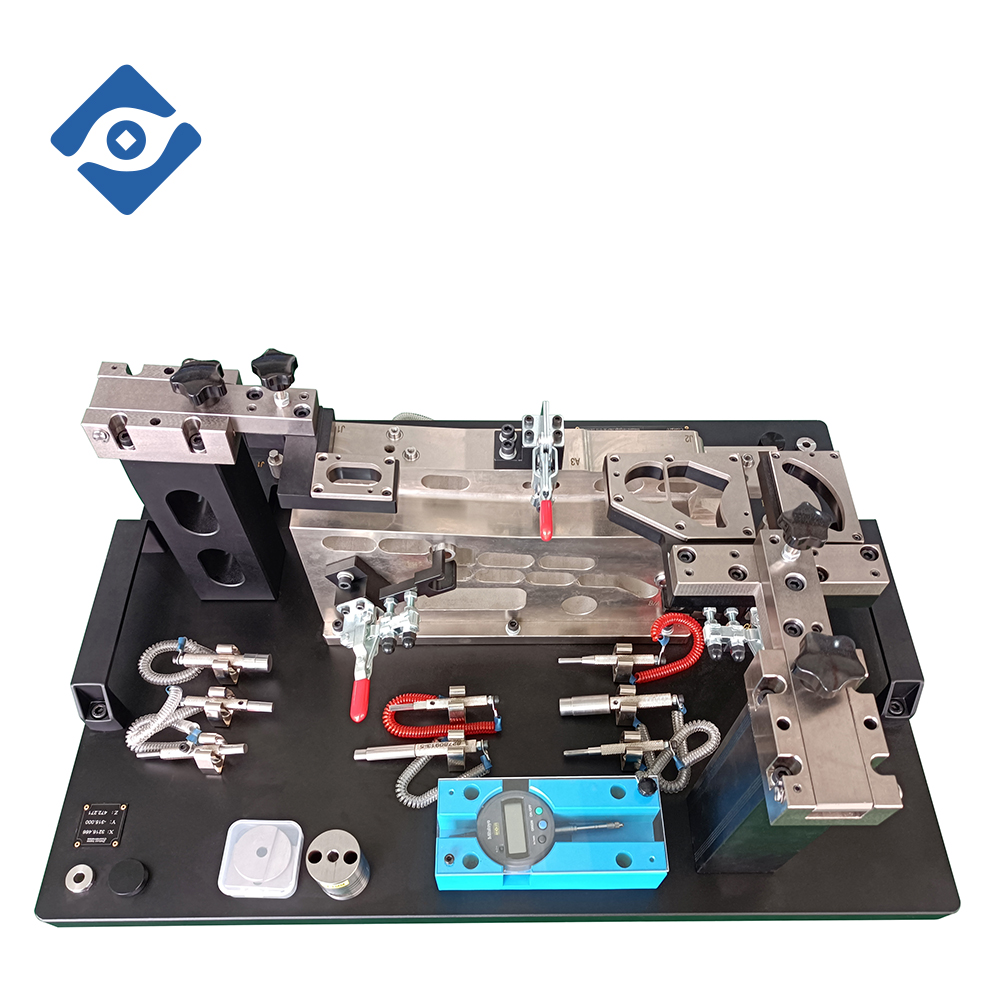

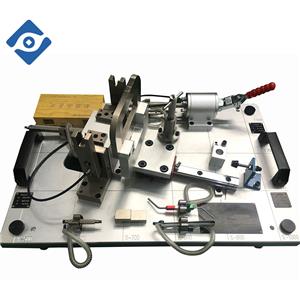

There are various names of parts in the non-standard parts of the inspection tool, such as the base plate, body, support, flipping mechanism, which belong to the category of non-standard parts. Different parts have different functions, and the equipment and process used are different. For example, the base plate and body are usually processed using CNC, while the support and flipping mechanism are generally processed using milling, grinding, and wire cutting processes. During the processing, it is also necessary to consider the different functional roles of the parts, The accuracy requirements for parts may also vary. In this case, it is necessary to have a process arrangement before production, such as Fidelity Inspection Fixture Manufacturer Co.,Ltd, which will have internal operating standards to guide operators on how to generally process automotive inspection tools. Different training will be provided for personnel in each different process, allowing technical personnel in different positions to grasp the technical essentials, thereby improving the quality and efficiency of work.

Each company may have different methods, but their goal is to produce a qualified part. For industry professionals, it is essential to understand how automotive inspection tools are generally processed, which is one of the most basic requirements. Of course, other technical abilities are also needed, and the so-called technical experience is constantly improved and summarized in the work.