How to plan the processing process of automotive checking fixtures?

How to plan the processing process of automotive checking fixtures?

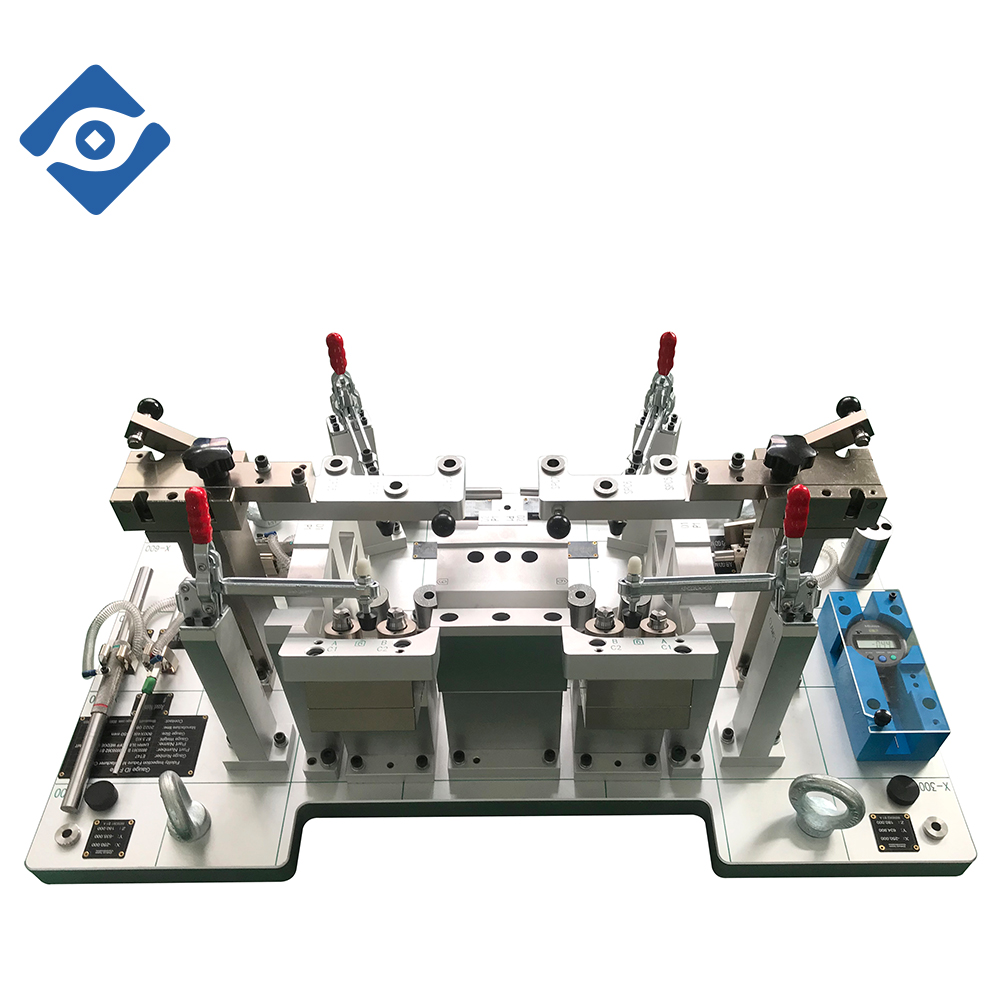

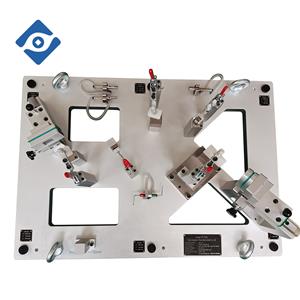

With the development of China's automotive industry, the application of automotive checking fixtures in modern industry is becoming increasingly widespread, and automotive checking fixtures have become an essential tool. Compared to previously used inspection tools such as calipers, micrometers, or projectors, automotive checking fixtures can detect automotive parts more quickly, thereby improving work efficiency.

If you want to make a good set of checking fixtures, the early processing technology is crucial. As a senior manufacturer in the checking fixture industry, Fidelity Inspection Fixture Manufacturer(Abbreviated as FIFM) has unique experience in this field. So, what is the best processing technology for automotive checking fixtures?

★ Well considered design

From the perspective of structural design, design engineers should carefully consider the feasibility of processing in the early stage of structural design, in order to create favorable conditions for later production and processing.

★ Selection of the material

Different materials have different characteristics, so their corresponding processing parameters are also different. The selection of materials should not only consider meeting the functions of the parts themselves, but also consider the convenience of processing. FIFM Company has its own standards, and different parts will use different materials and plan different processing processes.

★ Processing process requirements

From the perspective of production and processing, there are many types of optional equipment for processing, such as ordinary turning, milling, grinding, CNC machining centers, CNC lathes, deep hole drills, and even advanced five axis and seven axis machining centers. In practical applications, any part needs to choose different processing equipment based on the shape and dimensional accuracy requirements of the part itself, including the sequence of processing processes, So, only by planning the processing process of automotive checking fixtures can a qualified part be processed.

Of course, there are also other detailed requirements for the processing technology of automotive checking fixtures. You can refer to the relevant technical information of FIFM checking fixture for more information.