Are car checking fixtures and molds the same?

Are car checking fixtures and molds the same?

I have been working in the mold industry for many years without realizing it. Over the years, I have also gained a little understanding of automotive molds and checking fixtures. Is it the same for automotive checking fixtures and molds? Let's share this question briefly.

The car itself is assembled from a large number of parts, and only after passing various functional performance tests can it enter the sales market. In the early production of the car, molds and checking fixtures are indispensable. So are car checking fixtures and molds the same? What are the differences between the two?

Mold is a production tool for parts, with a wide range of applications, including stamping and injection molding, blow molding, forging and die-casting extrusion, etc. The product materials involve hardware, plastic, rubber, glass, etc. The mold is customized according to different products and technical requirements, and the materials and processing techniques used for different types of molds are also different. For example, the structure of plastic molds is composed of front and rear molds, the structure of a hardware mold is composed of an upper mold and a lower mold, and there are other types of structures that are different. Simply put, a mold is a specific product obtained by changing the shape of the material through different shapes and structures.

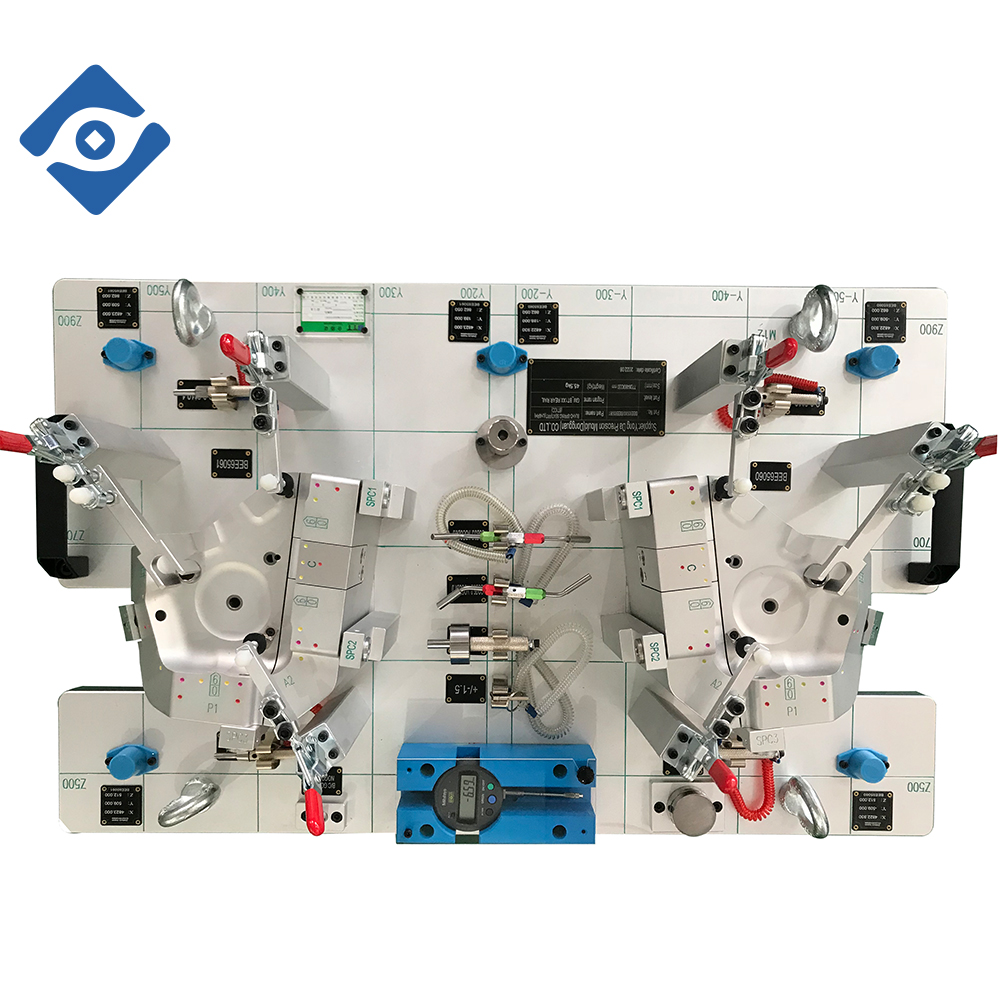

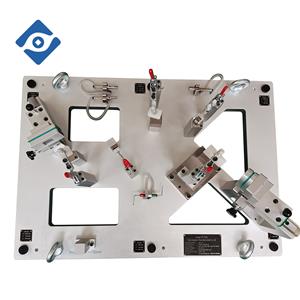

A checking fixture is a type of checking tool set up to detect a certain product, abbreviated as a checking fixture or automotive checking fixture. Currently, it is mostly used in the inspection of automotive parts. Checking fixtures are tools used to check whether the product conforms to the design data, whether plastic parts or sheet metal parts, they are all clamped onto the checking fixture to detect whether the product's geometric tolerance meets the design requirements.

The manufacturing of checking fixtures also has certain specific technical requirements, from design to processing and assembly, which are different from the methods of molds. I hope the above sharing is helpful to readers, and will never let this problem affects oneself again.

As a technical practitioner, the above are just personal insights. There are many different answers available on internet, and more technical content about automotive checking fixtures is available on the official website of FIFM checking fixtures!